In an unexpected career shift, Josh Paterson, owner of Northprint, transitioned from veggie farming to screen printing—a journey sparked by a workplace accident. While recovering, Josh explored the idea of starting his own clothing brand. What began as a passion project quickly turned into a new side hustle, as he set up a small print shop and began creating custom merchandise.

Like many entrepreneurs during the COVID-19 lockdown, Josh found himself deep in the world of screen printing. Inspired by the growing demand for custom apparel, he invested in a beginner’s screen printing kit and began experimenting. Fast forward to today, Northprint has expanded its services beyond screen printing to include digital transfers, embroidery, signage, and patches. With this broad range of offerings, it’s clear that Josh’s print shop is continuing to evolve—and we wouldn’t be surprised to see even more services added in the future.

By focusing on high-quality, custom products and constantly growing his skill set, Josh has positioned Northprint as a go-to provider for screen printing and related services in the industry.

Keep up to date with Northprint

Instagram: @northprint_merch

Website: https://www.northprint.com.au/

Email: josh@northprint.com.au

About Josh

List 3 things about yourself – fun facts, hobbies, pets or interests

- I was born in Zimbabwe

- I like to spearfish but get seasick (yes, it is awfully inconvenient)

- Before I started screen printing I managed a large vegetable farm. When I left, everyone in the area was confused that I was leaving to start printing t-shirts!

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

A few years ago I got run over at work. While I had some spare time I started a clothing brand like everyone else in 2020. I wanted to level up our quality so started to look into different print techniques and discovered screen printing. Before I knew it I had impulse bought a kit a few hours away and started my journey of learning a lot about what not to do and occasionally getting something right. It was challenging but super rewarding when I cracked something and I quickly found myself printing for others and the rest is history I guess!

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

Not long after I left my job to print full time I got a print job from Boeing Defence for some shirts for an exercise they were going on. It was the first 6 colour job I had printed and also the first time doing some decent halftone work. It took me longer to register than I’d like to admit and really kicked my ass dialling it in but it was one of those jobs I learned heaps on and the customer was stoked.

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

There seems to be a bit more interest in specialty inks and locations from customers, trying to stand out from the crowd. Like Matty from Heaps Good said, I hope these die a quick and painful death!

I see a lot of new technologies based on efficiency and job management emerging. I think in today’s market it’s super important for us to keep an eye on these and consistently keep improving to keep our businesses healthy.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

I’ve made a lot of good mates in the industry both in Australia and overseas. It’s super valuable to be able to share tips, ask a quick question when you’re tearing your hair out and have another opinion on what to be looking at to fix it. A rising tide lifts all ships.

What we do is complex and everything is custom so it’s not an easy line of work. Having a good community around reminds us that we’re not alone in the struggles we’re experiencing each day which I think is equally as important.

Shop Floor

What your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

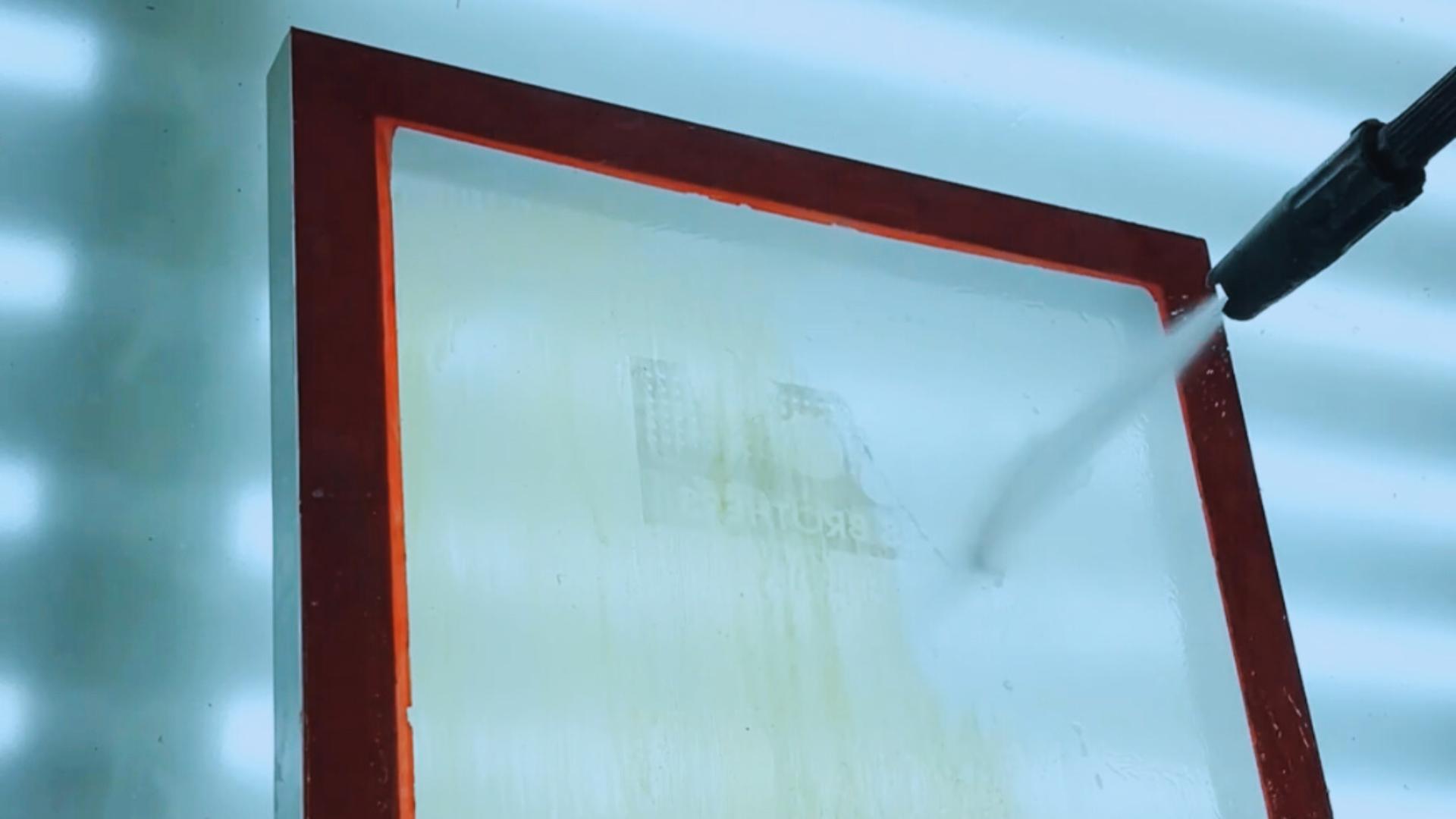

It’s got to be the dip tank! It’s not sexy and a bit of an investment but once you pull that first screen out and hit it with the pressure washer I’ll bet my last dollar that it’ll put a smile on your face! No one looks forward to reclaiming screens but a dip tank paired with some good chemicals means you can throw a podcast on and go on autopilot.

What is on your wish list for your shop floor this year?

It was an automatic but while writing this we just pulled the trigger on one! It needs a lot of love but once it’s set up I think the next best investment will be an auto coater for consistency.

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

I think the best advice is to just keep trying. You’re going to be frustrated and things aren’t going to work but if you just keep trying and problem solving it does get better…eventually haha! Don’t ignore the business side, make sure you know your numbers because you might be busy but you’ll find yourself wondering where the profit is. Also, please buy an exposure calculator ASAP! You’re going to use that bad boy more than you think and it will save you a lot of heartache.

Bonus

What’s your go-to playlist for a productive printing session?

You can’t beat a weird (I like to think of it as cultured) mix of EDM and country to keep you sane and let the neighbours know you’re still ok on those long runs!

Conclusion

A big thank you to Josh Paterson for being featured in October’s edition of Behind the Mesh. It’s always inspiring to hear the stories of screen printers who began with minimal equipment and grew their business into a thriving operation.

Northprint has become a trusted provider of custom merchandise for brands and businesses across Queensland. With a rapidly expanding client base, the company has already outgrown several locations. As Northprint continues to grow, it’s only a matter of time before we see them moving into a larger facility to meet the increasing demand for their screen printing and custom apparel services.

Written by the Jones Brothers Printechnology Team in collaboration with Northprint, Josh Paterson.