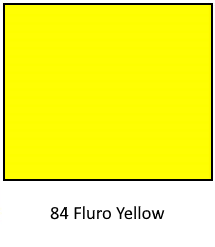

Description

Universal Vinyl Ink Series – High Gloss Solvent Ink for Vinyl & Coated Surfaces

Universal Vinyl is a solvent-based screen ink designed for high-speed production on vinyl and vinyl-coated substrates. Known for its rapid drying and glossy finish, this ink delivers flexible and vacuum-formable prints that are ideal for signage, decals, and industrial vinyl applications.

Engineered to bond tightly with a broad range of surfaces, Universal Vinyl achieves excellent print quality whether applied by hand or automatic screen printing equipment.

Key Benefits:

- Fast-drying, high-gloss solvent-based formulation

- Exceptional adhesion to vinyls, A.B.S., Lexan®, acetates, and banner materials

- Flexible ink film suitable for vacuum forming

- Outdoor durability up to 4–5 years when overprinted with Pro-Pack Clear

- Compatible with mono filament mesh (62T–140T) and solvent-resistant emulsions

Recommended Substrates:

- Pressure-sensitive vinyl

- Vinyl-coated banners and products

- A.B.S., Lexan®, and acetate films

Not suitable for polyethylene or polypropylene substrates.

Recommended Emulsions:

For best stencil integrity and performance with Universal Vinyl inks, use solvent- and UV-compatible emulsions such as:

- Murakami SR

- Chromaline UDC ACE

- Saati SAATIGRAF HS3

- Saati Grafic HU

You can find these in our Solvent & UV Emulsions collection.

Drying & Durability:

Jet dry in seconds, touch dry in 5–10 minutes. Full through-cure typically occurs within 72 hours under optimal conditions. Outdoor life of 4–5 years achievable with Pro-Pack Clear overcoat (required for metallic inks).

Thinning & Additives:

- Thin up to 15% with FQV180 Thinner or slow drying with FQV182 Retarder

- FQV170 Clear for adjusting colour strength (not suitable as exterior clear coat)

- FSU178 Sharp Print Compound for fine detail (may reduce gloss)

- Up to 10% FSU5935 Flattening Paste for matte finishes

For extreme durability, overcoat prints with ASI Pro-Pack Clear FSU3780/3781.

Opacity & Lightfastness:

Available in standard and Pantone-matching colours. Most standard shades offer excellent opacity and lightfastness. Lighter tints and extended colours may show reduced fade resistance.

Important Notes:

Always stir before use and conduct substrate testing prior to production. Solvent-sensitive substrates may cause ink re-dissolution. Refer to SDS before handling.

For more information on this product, find the technical data sheet here.

Reviews

There are no reviews yet.