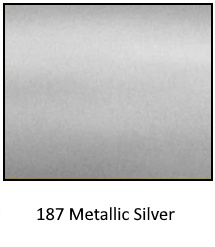

Description

Two Can Epoxy – High Adhesion Two-Pack Ink for Industrial Substrates

Two Can Epoxy is a high-performance, two-pack screen ink system designed for exceptional adhesion, chemical resistance, and durability on a wide range of challenging surfaces. Ideal for industrial applications, this ink cures via polymerisation and requires the addition of catalyst FER176 to activate the drying process.

It is suitable for use on most metals, glass, treated polyethylene, treated polypropylene, and powder-coated surfaces. Two Can Epoxy is not recommended for vinyl substrates or prolonged outdoor exposure unless overcoated with a suitable protective layer.

Key Benefits:

- Excellent adhesion to difficult substrates

- Outstanding resistance to solvents and chemicals

- High-gloss finish with excellent opacity

- Custom colour options available on request

- Available in 9 standard and 8 Pantone base colours plus black and white

Recommended Substrates:

- Metals

- Glass

- Treated polyethylene and polypropylene

- Powder-coated surfaces

Recommended Emulsions:

To ensure stencil longevity and chemical resistance with Two Can Epoxy inks, we recommend the following solvent-compatible emulsions:

- Murakami SR

- Chromaline UDC ACE

- Saati SAATIGRAF HS3

- Saati Grafic HU

View the full range in our Solvent & UV Emulsions collection.

Screen Setup:

- Mesh: 62T–140T monofilament

- Stencil: Any solvent-resistant or dual-cure emulsion

- Coverage: Approximately 40 m²/kg

Mixing & Usage:

Mix 4 parts ink with 1 part catalyst FER176. Allow 5 minutes for the induction period before use. Only mix quantities needed for 5–6 hours of printing, as the ink will gel beyond that window.

Drying & Curing:

- Touch dry: ~2 hours (ambient)

- Full air cure: 7–10 days

- Force cure options:

- 120°C for 10 minutes

- 150°C for 7 minutes

- 180°C for 4 minutes

Cleaning & Thinning:

- Wash-up: FER180

- Thinner: FER180 (up to 10%)

- Retarder: FER182 (use as needed to slow drying)

Important Notes:

- Always stir well before use and pre-test on target substrates

- Do not use on vinyl surfaces without pre-testing

For more information on this product, find the technical data sheet here.

Reviews

There are no reviews yet.