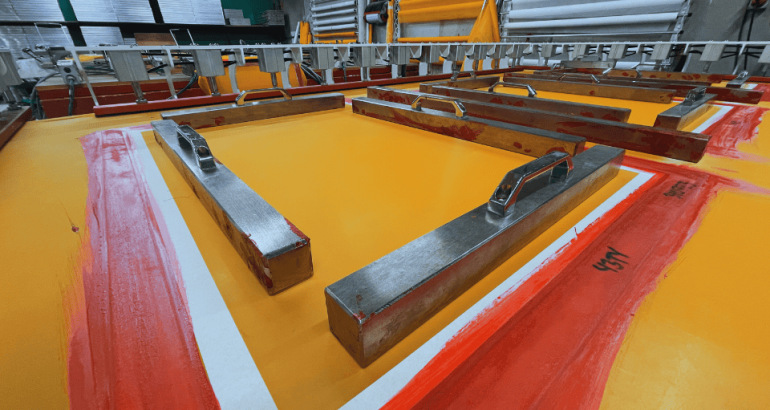

Your screen mesh is an important part of your print process. It can make or break a print job. Experienced printers will advise that high quality mesh and well tensioned screens will give you sharp and crisp prints

every time.

We’ll discuss why it’s important to regularly check your screens for holes and tension dips.

What are some signs that my screen needs a re-mesh?

Loss of tension

This can occur due to the screen undergoing a very long print run or has been used a lot for various print jobs. Each print you do places stress on your screen mesh, over time and a lot of prints, the tension will weaken.

Holes in the mesh

Holes in screens are a common occurrence. They can occur due to a range of reasons but not limited to wear and tear, mishandling and age of the mesh. Like any material, your screen mesh will break down over time, especially if the screen has been used for many print jobs.

Ripped mesh

Ripping your mesh is a rite of passage as a printer. You may accidentally rip it due to placing too much strain near the glue line or even doing something silly like having a sharp object near your screen. Once your mesh is ripped/torn, the tension around the area of the rip/tear will drop significantly.

Frame glue breaking down

Frame glue will inevitably breakdown over time. The pressure from your squeegee (auto or manual) will contribute to the break down frame glue. Post print/screen reclaiming chemicals can affect the chemical

make up of the glue, depending on what is used – further adding to the degrading of the glue.

What are the benefits of re-meshing my screens even though the mesh isn’t damaged?

Print quality – This is a major part producing great prints. Having well tensioned screens will provide a sharper print and reduce your ink consumption per print, in turn saving you money.

If my screen feels like it has less tension than it used to, will that need a re-mesh? Why?

As above, the print tension is critical.

It is especially critical if you are running a multi colour job. You should always use screens with similar tension to avoid having registration issues arise. It will provide you with far shaper print edges and higher

overall print quality.

If your screen tension feels considerably lower than your other screens, consider booking it in for a re-mesh.

3 Quick Tips to Maintain Your Mesh

Tip 1: Use a good quality press wash so it won’t affect your frame adhesive.

Tip 2: Don’t leave any haze remover on too long it can burn a hole in the mesh.

Tip 3: If the mesh is over 72 months old, renew the mesh as its already paid for itself. At Jones Brothers the date of the last remesh is written onto the glue of your screen, so this will be easy for you to check.

Why You Should Re-mesh Your Screens

Product Recommendations

1, PMI Tape or any rubber adhesive

tape

Leaves minimal residue and gentle on your mesh & emulsion.

2. Ultimate Clean Up Cards

No sharp or hard edges and corners to protect your mesh.

3. Plastic Spatulas

Curved edges to protect our mesh.