Understanding Diazo in Screen Printing Emulsions: A Complete Guide

If you’ve been screen printing for a while, you’ve probably heard the term “diazo” thrown around when talking about emulsions. But what exactly is it? And why is it so important in the stencil-making process? Whether you’re a beginner or a seasoned printer, understanding diazo will help you get better results in your prints.

In this blog, we’ll break down what diazo is, how it works, and why it’s an essential part of many emulsions—without the confusing chemistry jargon!

What is Diazo?

Diazo is a light-sensitive chemical compound used in screen printing emulsions. When mixed into an emulsion, it makes the coating react to UV light, allowing you to create detailed stencils for printing.

Think of diazo as a baking ingredient. Before it’s exposed to heat (or in this case, light), it stays soft and flexible. But once heat (UV light) is applied, it transforms, hardening into a permanent structure—just like dough turning into bread!

Diazo-based emulsions are widely used because they are affordable, reliable, and great for capturing fine details in prints.

What is Diazo Made Of?

Diazo isn’t just one thing—it’s a combination of different chemical components that work together. The key ingredient is diazonium salts, which are what make the emulsion light-sensitive. Here’s a simple breakdown of what goes into diazo:

🔬 Diazonium Salts – The main light-reactive ingredient.

💧 Water or Solvent Carrier – Helps dissolve and spread the diazo evenly into the emulsion.

🛡️ Stabilizers – Prevents the diazo from breaking down too quickly.

🔗 Binding Agents – Ensures the diazo mixes well with the emulsion for an even coating.

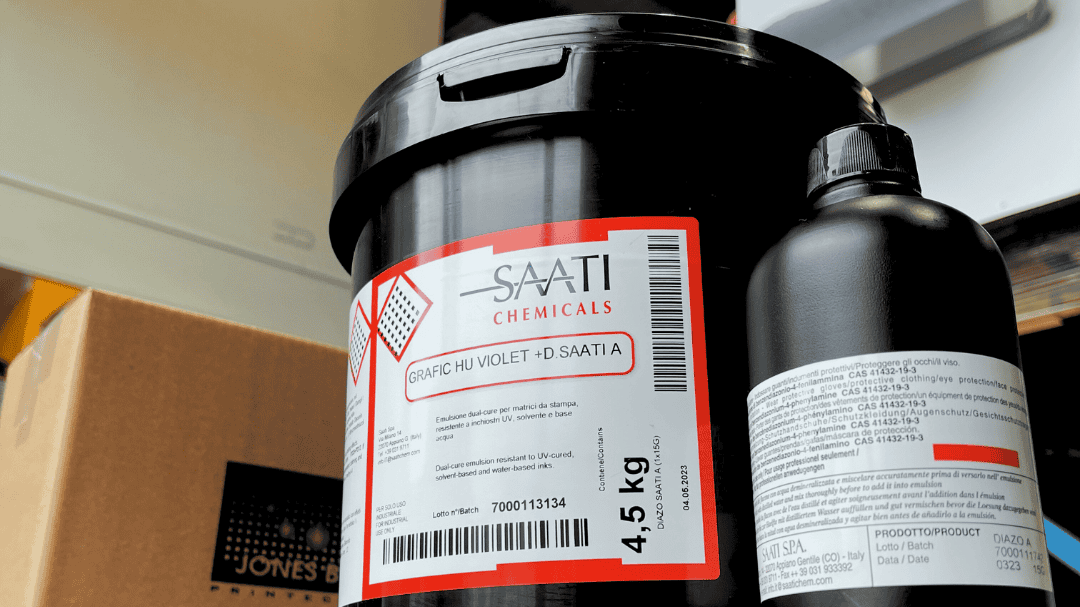

Before being added to an emulsion, diazo is typically a powder or a liquid that needs to be mixed in. Once combined, the emulsion becomes light-sensitive and ready for use!

The Chemistry of Diazo in Emulsion

Here’s where things get really interesting! Diazo works through a UV-activated chemical reaction.

1️⃣ Before Exposure: The diazonium salts in the emulsion are stable and water-soluble, meaning they can be easily washed out with water. The coated screen is still soft at this stage.

2️⃣ During Exposure: When UV light hits the emulsion, it breaks down the diazonium salts, causing a polymerization reaction—this is just a fancy way of saying that the molecules start linking together to form a hard, water-resistant layer.

3️⃣ After Exposure: The areas of the screen that received UV light stay hardened, while the areas that were blocked by the film positive (your design) remain soft and wash out with water, leaving behind the open stencil.

🔬 Think of it like developing a photograph—light hardens the exposed parts while the unexposed areas can be rinsed away, revealing the image!

Why is Diazo Necessary?

So, why go through all this trouble? Can’t we just use emulsions without diazo?

Not really! Diazo-based emulsions are incredibly versatile, affordable, and effective. Here’s why they’re a staple in screen printing:

✅ Works with Various Ink Types – Diazo emulsions are great for plastisol, water-based, and solvent-based inks, making them perfect for different printing styles.

✅ High Resolution & Detail – The ability to capture fine lines and halftones makes diazo emulsions ideal for detailed prints.

✅ Affordable & Accessible – Diazo emulsions are cost-effective, making them great for both beginners and professionals.

✅ Strong & Durable – Once properly exposed, diazo emulsions hold up well on long print runs.

However, diazo does have some drawbacks, which leads us to our next section…

Pros & Cons of Diazo Emulsions

Just like any screen printing material, diazo emulsions come with strengths and weaknesses.

✅ Pros:

✔ Cost-Effective – Cheaper than other emulsion types.

✔ Great for Detailed Prints – Ideal for fine lines and halftones.

✔ Versatile – Compatible with different ink types.

✔ Easy to Reclaim – Stencil can be removed with standard emulsion removers.

❌ Cons:

✖ Longer Exposure Time – Takes longer to expose than pure photopolymer emulsions.

✖ Shorter Shelf Life – Once mixed, it only lasts a few weeks before losing sensitivity.

✖ Must Be Stored Properly – Needs to be kept cool and in the dark to prevent premature exposure.

If you’re new to screen printing, these downsides aren’t deal-breakers—but they are important to keep in mind!

Tips for Using Diazo Emulsions

Want to get the most out of your diazo emulsion? Follow these best practices:

📌 Mix Only What You Need – Diazo emulsions have a limited shelf life, so don’t mix a whole batch unless you plan to use it quickly!

📌 Store It Properly – Keep your emulsion in a cool, dark place to prevent premature exposure. Check the product or technical data sheet for storage recommendations – each emulsion brand can vary.

📌 Use Yellow Safelight – Work under yellow or low-wattage lighting to avoid accidental exposure.

📌 Check Your Exposure Times – Underexposure leads to weak stencils that break down easily, while overexposure can make washout difficult.

📌 Reclaim Screens Correctly – Use an emulsion remover to strip your screen when you’re ready for a new stencil.

Following these steps will extend the life of your emulsion and improve your print quality!

Final Thoughts

Diazo might sound complicated at first, but once you understand how it works, it becomes a powerful tool in your screen printing arsenal. Whether you’re printing t-shirts, posters, or stickers, diazo-based emulsions offer precision, durability, and versatility at an affordable cost.

If you’re just starting out, give diazo emulsions a try—they’re a great way to learn stencil-making without breaking the bank. And if you’re already experienced, refining your knowledge of diazo can help you troubleshoot issues and improve your overall workflow.