The essential guide for Australian screenprinters chasing clean, bright, consistent white prints.

WHY POLAR WHITE EXPOSES EVERY FLAW IN YOUR TECHNIQUE

If there’s one ink that will humble even the most seasoned screenprinter, it’s Polar White.

Every shop in Melbourne, across Australia, and honestly across the planet has fought with it:

- Chalky prints

- Patchy coverage

- Wicking into the fibres

- Muddy edges

- Dull underbases

- Inconsistency between shirts

Polar White doesn’t forgive shortcuts, guesswork, or brute force.

It demands finesse, clean technique, and actual understanding of ink behaviour — not the “just push harder” approach that ruins prints across the country daily.

This guide breaks down exactly why Polar White behaves the way it does and how to print it properly so you get bright, smooth, high-opacity results every time.

Let’s go through the mesh.

THE SCIENCE BEHIND POLAR WHITE: SURFACE DEPOSIT VS FIBRE SATURATION

Most screenprinters assume white ink behaves like any other plastisol.

It doesn’t.

Polar White (and other premium high-opacity whites) is designed for surface laydown.

It wants to sit on top of the garment fibres, not soak into them.

That’s what gives you:

- Smooth feel

- High brightness

- Crisp edges

- Strong opacity under colours

When you push too hard, you break this natural behaviour.

Too much squeegee pressure forces the ink into the garment, causing:

- Wicking

- Loss of opacity

- Grainy texture

- Fuzzy edges

- A duller, greyer white

So before you think about printing, understand this truth:

Polar White isn’t a force problem. It’s a control problem.

THE MOST COMMON MISTAKE: TOO MUCH PRESSURE

If your Polar White looks:

- Faded

- Chalky

- Patchy

- Inconsistent

Or like it’s “disappearing” into the garment…

…you’re almost definitely printing with far too much pressure.

More pressure does not equal more opacity.

More pressure equals more fibre disturbance and faster wicking.

What’s happening under the squeegee is simple:

you’re pushing the ink down instead of across.

And once those fibres drink the ink, you’re done.

No flash cure, no second stroke, no magic trick will fix it.

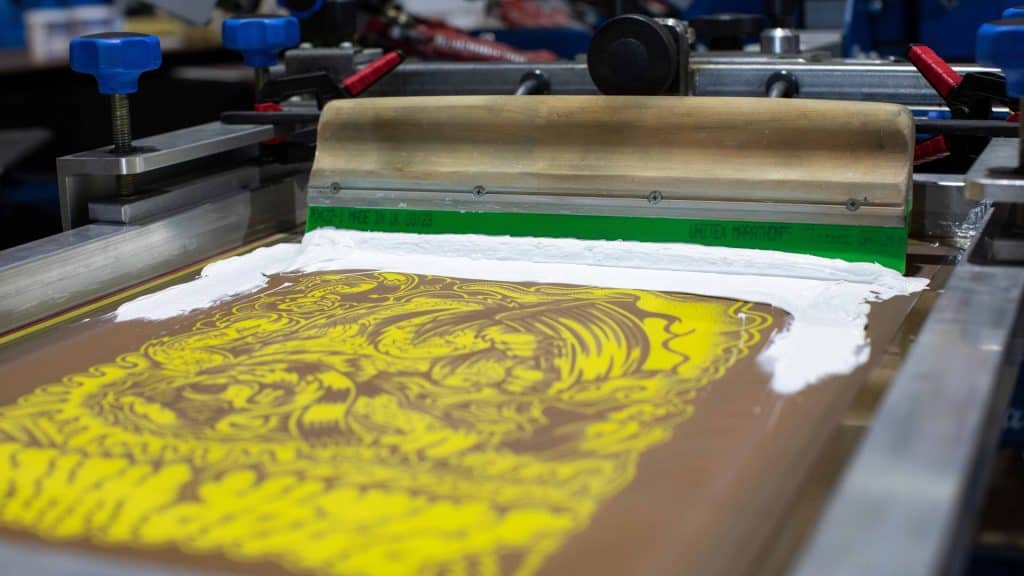

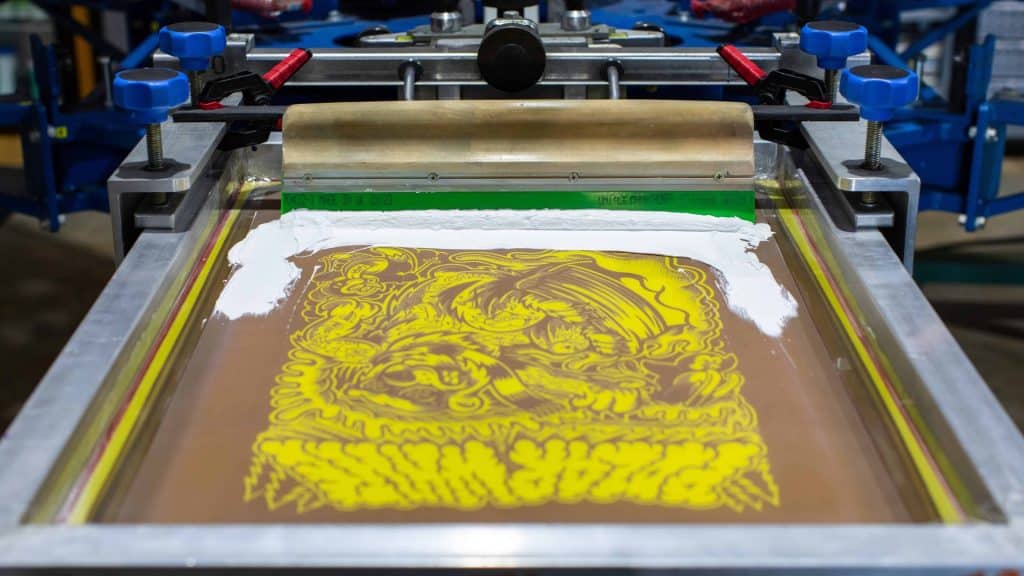

THE SOLUTION: SHEAR THE INK — DON’T SMASH IT

The correct way to print Polar White is to shear, not force.

A proper shear stroke:

- Transfers the ink across the stencil cleanly

- Leaves a controlled deposit sitting on the surface

- Keeps the fibres undisturbed

- Maintains opacity and clarity

Here’s what that actually looks like in practice:

The Correct Polar White Technique

- Use lower pressure — less than you think

- Keep a sharp squeegee blade

- Run a 10–15° angle off vertical

- Use a consistent, smooth stroke

- Avoid double-stroking unless absolutely required

- Flash lightly — just to gel, never overbake

Your goal is not penetration.

Your goal is surface deposit.

HOW TO PREVENT WICKING IN THE FIRST PLACE

Wicking is the enemy of bright whites.

It’s also completely preventable once you understand what causes it.

What triggers wicking?

- Excess pressure

- Excess heat during flashing

- Thin deposits

- Ink forced into the fibre structure

- Fabric pulling ink downwards via capillary action

How to stop it

✔ Reduce squeegee pressure

✔ Switch to a slightly softer stroke

✔ Use a sharp, well-maintained blade

✔ Don’t over-flash — gel ONLY

✔ Use a mesh count appropriate for a solid white (no unnecessary highs)

✔ Keep print strokes consistent (no overworking the area)

Good Polar White printing is about doing less, not more.

THE PAYOFF: WHAT HAPPENS WHEN YOU GET IT RIGHT

When you print Polar White correctly, you’ll see it immediately:

✔ Brighter whites

Because the ink is reflecting light from the surface — not trapped inside the fibres.

✔ Smoother hand feel

Surface laydown = fewer visible fibres = premium finish.

✔ Sharper edges

Reduced fibre disturbance eliminates fraying, fuzzing and bleed.

✔ Better top colours

A clean white base boosts vibrancy and detail in every subsequent colour.

✔ Faster consistency across the run

Good technique minimises variation — critical for retail-level production.

This is why Polar White is loved by printers who learn to control it.

It’s not just white ink — it’s a standard of quality.

FINAL THOUGHTS: POLAR WHITE MAKES YOU A BETTER PRINTER

It’s brutally honest.

It shows your pressure issues.

It exposes your stroke inconsistencies.

It punishes over-flashing.

It magnifies your mesh selection choices.

But once you master Polar White, everything else becomes easier.

Your technique gets cleaner.

Your prints get sharper.

And your confidence — especially under pressure — skyrockets.

If you’re a screenprinter in Melbourne or anywhere in Australia trying to level up your white printing, this is the place to start.

Written by Jones Brothers Printechnology with the findings from BlackDog Ink.