THE POLAR WHITE PROJECT

AS Colour x Union Ink

Project Partners

Welcome to The Polar White Project

This isn’t just another product demo — it’s a deep dive into real-world results. We teamed up with one of Australia’s most respected print shops to put Union Ink’s UPLC Polar White through its paces. From soft-hand finishes to serious bleed-blocking power, this project showcases how Polar White performs under pressure, on tough garments, and in high-demand production environments.

Explore the process, the prints, and the feedback from the experts who live and breathe screenprinting.

This is the Polar White Project — where theory meets pressroom.

Project Partners:

AS Colour, Union Ink, BlackDog Ink

Artwork:

Sigh Luxton

Photos & Video:

Brad Collins

PROJECT GALLERY

Polar White Facts

Superior Opacity & Coverage

Maximum opacity on dark blends with fewer strokes. Crisp, bright prints — even on poly-heavy fabrics.

Soft, Creamy Consistency

Print-ready and easy to work with. Glides through mesh cleanly with excellent detail hold.

Low Bleed, High Confidence

Formulated to combat dye migration on fleece and blends. Say goodbye to ghosting or tinting.

Low Temp Cure, Energy Saving

Cures at just 132°C. Reduces migration, saves energy, and keeps prints consistent job to job.

Matte Finish & Soft Drape

No plasticky shine. Just smooth, matte colour and a retail-grade hand feel your customers will love.

Halftone-Friendly Detail

Holds halftones and fine art with precision. Great for high-res screens and fine mesh printing.

THE POLAR WHITE CASE STUDY

UNION INK POLAR WHITE x AS COLOUR STENCIL HOOD

Printed by BlackDog Ink

PRINTING

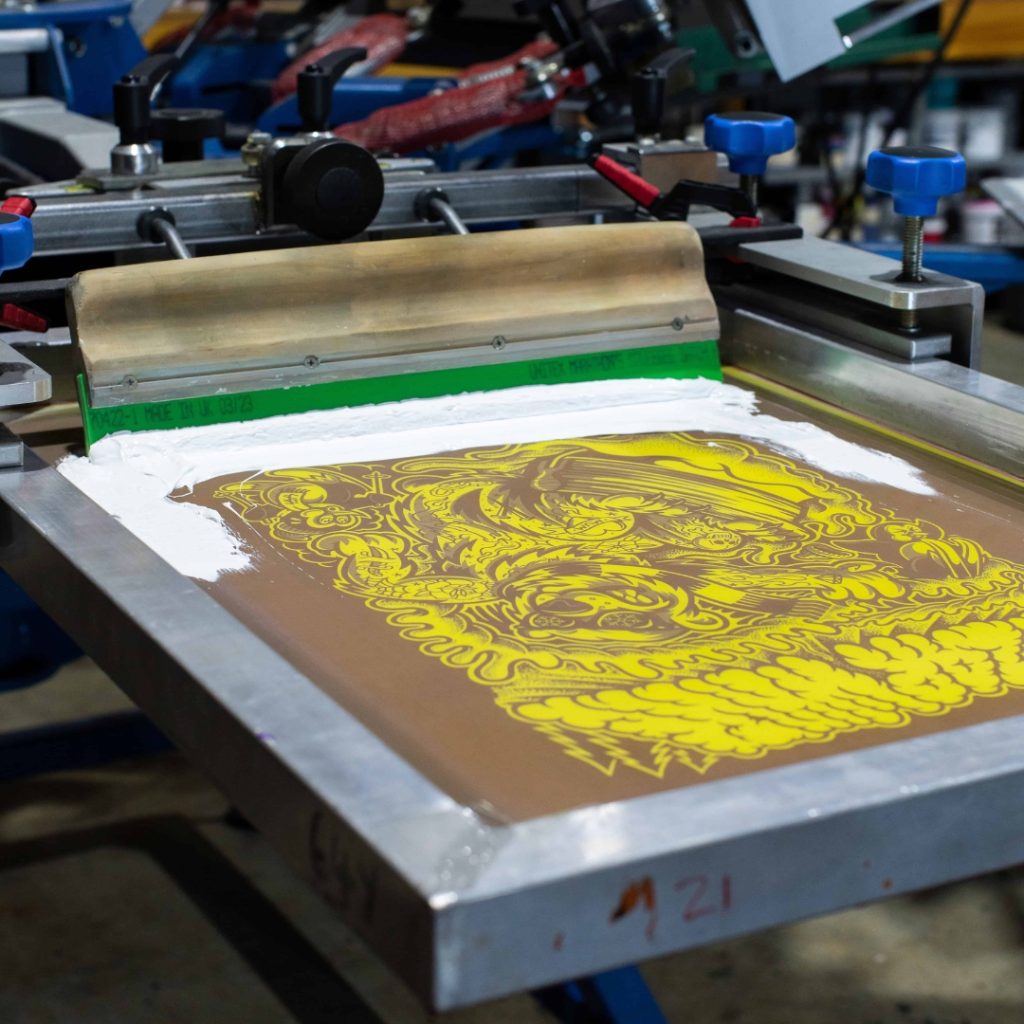

Each hoodie is handprinted by Chris on his modified M&R manual carousel.

RESOLUTION

Printed through 64T and 77T mesh, selected by Chris, allowed the artwork to be printed as sharp as possible.

MIXING

Jones Brothers supplied the inks and mixed PMS 7 C Grey and 637 C Blue with Union Ink Unimix ink range.

FLASH & CURING

Flashed with an infrared flash dryer for 4-5 seconds and cured in a conveyor oven at 140°C to 150°C for 60 seconds.

🧊 Polar White Project: Real-World Case Study with Blackdog Ink

When we decided to put Union Ink’s new UPLC Polar White to the test, we knew there was one print shop we had to call — Blackdog Ink.

Led by head printer Chris — widely regarded as one of Australia’s top screenprinters — Blackdog Ink is known for producing ultra-detailed work across both water-based and plastisol ink systems. Chris’s precision, eye for colour, and technical mastery made him the ideal partner to stress-test Polar White on one of the most challenging garments in the industry: the black AS Colour Stencil Hoodie.

This hoodie is notorious for dye migration. Our goal? See if Polar White’s low-bleed properties could stand up to real-world conditions. The result? A stunning 80-hoodie run printed entirely by hand on Chris’s manual carousel — delivering soft-hand feel, ultra-bright white, and smooth colour laydown using a combo of Polar White and Union Ink’s UPLC Unimix range.

🐾 Meet Blackdog Ink

Based in Port Macquarie, NSW, Blackdog Ink is led by Chris, a recognised master in the Australian screenprinting community. With a fully customised M&R manual press and an automatic carousel for large jobs, Blackdog prints everything from fashion streetwear to corporate merch — with AS Colour blanks being their staple.

🧵 The Hoodie Struggle: Why White Ink on Fleece is a Problem

Dye migration on blended hoodies is a challenge even veteran printers face. Dyes used in polyester garments can bleed through during curing, turning bright whites into dull greys or pinks. The AS Colour Stencil Hood — an 80% cotton / 20% polyester fleece — was the perfect test.

- High-poly blends are difficult to control

- Large white prints are especially vulnerable

- Customers see results, not the technical struggle

This is why Polar White had to go beyond the press — it had to hold up in the client’s hands too.

❄️ Enter Union Ink UPLC Polar White

Polar White isn’t just a white ink — it’s a game-changer.

- Soft and creamy out of the bucket, even in cold shops

- Low-cure temp (as low as 132°C) reduces dye migration

- Ultra-bright, matte white finish

- High-opacity and detail-holding on dark blends

- Performs smoothly on high-speed autos

In every test, Polar White outperformed Blackdog’s previous white ink across coverage, feel, and clarity.

🧪 Putting Polar White to the Test

With the hoodie market booming in winter, it was time to see how Polar White would perform under real-world production pressure. Here’s how the job broke down:

| Spec | Details |

|---|---|

| Garment | 80 × AS Colour Stencil Hood (Black, 80% cotton / 20% polyester) |

| Design | 3-colour print, using black garment as fourth “colour” |

| Shop | Blackdog Ink |

| Carousel | Manual |

| Mesh Used |

Screen 1: 64T - Polar White Screen 2: 77T - Polar Grey 7C Screen 3: 77T - Polar Blue 637C Screen 4: 77T - Polar White |

| Flash & Cure Temps | Flash - Infrared - 4–5 secs Curing range: 140–150°C for 60 seconds |

Polar White held its own across all 80 hoodies — zero migration, crisp edges, and a silky-soft hand feel.

🎨 The Print, The Feel, The Finish

The print had immediate visual appeal: bright, soft, and clean. No fibrillation. No gloss. And best of all — no migration.

- Smooth matte finish

- Super sharp linework with zero blur

- UNI MIX colours added bold contrast and vibrancy

✅ What Blackdog Ink Thinks Now

Polar White is now a staple in Blackdog Ink’s lineup. It's replaced multiple other white inks, simplifying their workflow without sacrificing quality. Chris has already recommended it to other shops — and those shops have already made the switch too.

Even long-term clients have seen the change. One legacy customer’s entire ink system was updated to Polar White and UNI MIX after this project’s success.

🚀 Ready to Print Like Blackdog Ink?

Get your hands on Polar White and experience the difference. Whether you’re fighting dye migration or just looking to upgrade your whites, this is the ink built to deliver.

APPRECIATIONS

This project was made possible by the amazing collaborative partners. Thank you to Elijah and the team at AS Colour, Chris & Erin from BlackDog Ink and the team at Union Ink.

The incredible artwork was completed by Sigh (Simon) Luxton.

Amazing project photos and videos of the printing of the Polar White Project hoodie by Brad Collins.

And a thank you to every print shop who took the time to give us their thoughts on Polar White.

FAQ

have A QUESTION?

HOURS

Monday to Friday

8:00 AM – 4:30 PM

Feel free to reach out during these hours!

PH: +613 9357 5767

E: info@jonespt.com.au

IG: @jonesptaus

HOW TO ORDER?

- To place an order, customers must send an email to info@jonespt.com.au

or send a DM via Instagram (@jonesptaus) with the details of the

items you wish to purchase. - Orders are subject to availability, and stock is limited. Orders will be

confirmed by a member of our team. - Orders are not finalized until confirmation has been sent from our customer

service team.

SHIPPING & Delivery

Shipping costs can be influenced by several key factors:

- Location: Shipping to rural or remote areas tends to be more expensive compared to metropolitan regions.

- Order Size: Larger orders often result in higher shipping costs due to weight and packaging requirements.

- Hazardous Goods: Certain products, classified as dangerous goods, require special handling and regulations, which increase shipping costs.

We strive to provide you with the most affordable shipping options, ensuring that your costs are minimized while maintaining safe and timely deliveries.