UNI MIX: PROJECT POSEIDON

UNION INK x AS COLOUR

Project Partners

Welcome to UNI MIX: Project Poseidon

Where colour meets creativity.

Project Poseidon is our bold new campaign dedicated to showcasing the power and precision of the Union Ink UNI MIX mixing system. Known for its unmatched colour accuracy, smooth printability, and wide range of vibrant mixing bases, UNI MIX gives printers the tools to bring any vision to life — from exact Pantone® matches to striking custom shades.

This project brings together the best in design, print, and garment quality to put UNI MIX front and centre. We’ve teamed up with:

-

BlackDog Ink – (@blackdog_ink) masters of screenprinting

-

Minnie Longstaff (@minfinite_) – an artist whose style is bold, vibrant and detailed.

-

AS Colour – supplying the premium black Staple Tee, the perfect canvas to showcase the depth and vibrancy UNI MIX delivers.

- Union Ink – The ink brand that has stood the test of time. Supplying the incredible UNIMIX inks for this project.

With Project Poseidon, we’re diving deep into the possibilities of colour — and inviting the industry to see just how far UNI MIX can go.

Artwork: Minnie Longstaff

Photos & Video: Brad Collins

PROJECT GALLERY

I’m always thinking about how a design will live off the screen and out in the real world. Bold lines, deliberate colour choices and a sense of movement are what keep the work feeling alive, even when it’s frozen in print.

Minnie Longstaff

Tattooist · Digital Illustrator

UNI MIX Facts

Pantone®-Simulated Colour Matching

Accurately reproduces standard Pantone® colours and Union Ink standard colours for consistent, on-brand results.

15 Mixing Components

Uses 15 highly opaque, versatile bases to create bright, vibrant, and accurate colour matches for any project.

Flexible Cure Range

Cures between 270°F and 320°F (132°C–160°C) to save energy, protect fabrics, and reduce dye migration.

Multi-Fabric Compatible

Performs beautifully on cotton, tri-blends, cotton/poly blends, and polyester with proper underbase for bleed-prone fabrics.

Wet-on-Wet Printing

Excellent opacity and clean detail using 43T–90T t/cm mesh, ideal for efficient, multi-colour print runs.

Internationally Compliant

Non-phthalate and meets global compliance standards for safer printing and consumer peace of mind.

The thing that surprised me most was the opacity and vibrancy. The reds and yellows were way more vibrant than I expected, and even when we reduced the yellow by about 10%, it was still bright, punchy and properly opaque over the Polar White base.

Chris Mez

BlackDog Ink · Screenprinter

PROJECT POSEIDON CASE STUDY

UNION INK - UNI MIX x AS COLOUR STAPLE TEE

PRINTING

Clean wet-on-wet performance across 100T–120T mesh.

RESOLUTION

Clears high mesh counts effortlessly. Fine detail stays sharp while colours remain bright, opaque, and punchy over Polar White.

MIXING

Creamy straight from the pot. No tarry drag, easy to mix, highly vibrant yellows and reds — even after a 10% reduction.

FLASH & CURING

Polar White needs precise flashing. UNIMIX cures best low and slow — ~1 min dwell, 135–150°C exit temp, no bubbling unless overheated.

📘 In-Depth Case Study: UNIMIX UPLC Mixing System

Project Poseidon collaboration – BlackDog Ink × AS Colour × Union Ink – Project led by Jones Brothers Printechnology

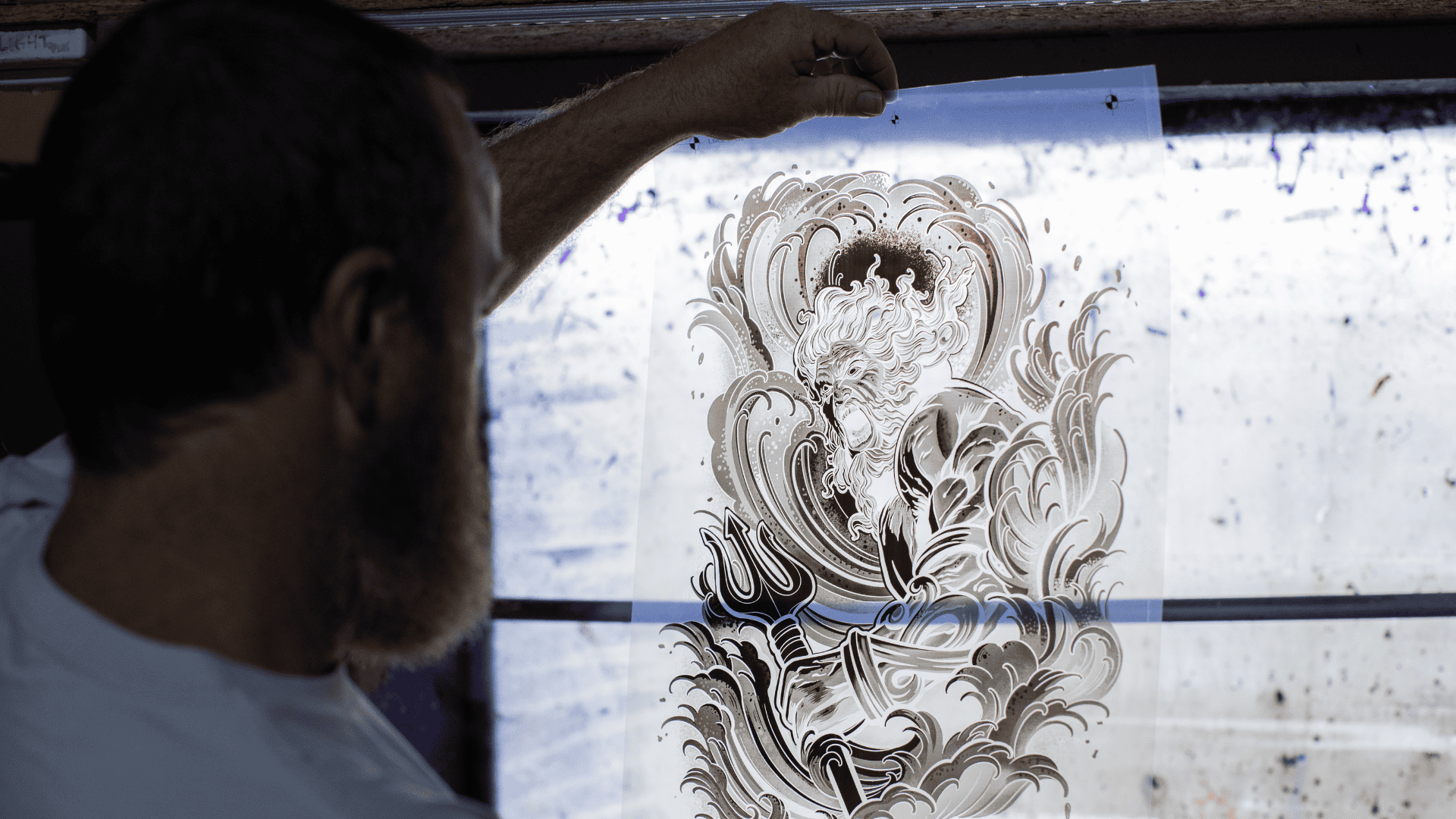

Early concept artwork for Project Poseidon prepared for screenprinting in Melbourne, Australia.

Introduction: A Project Built on Control, Consistency & Colour Fidelity

Project Poseidon demanded colour accuracy, durability, clean mesh behaviour and a premium hand feel — all while running high-volume, multi-layer prints across mixed garments and mesh counts.

BlackDog Ink needed a mixing system that was:

- Predictable

- Consistent

- Vibrant

- Easy to work with

- Stable across long runs

- Compatible with Polar White as the underbase

The Union Ink UPLC UNIMIX mixing system was selected for its reliability and Pantone accuracy.

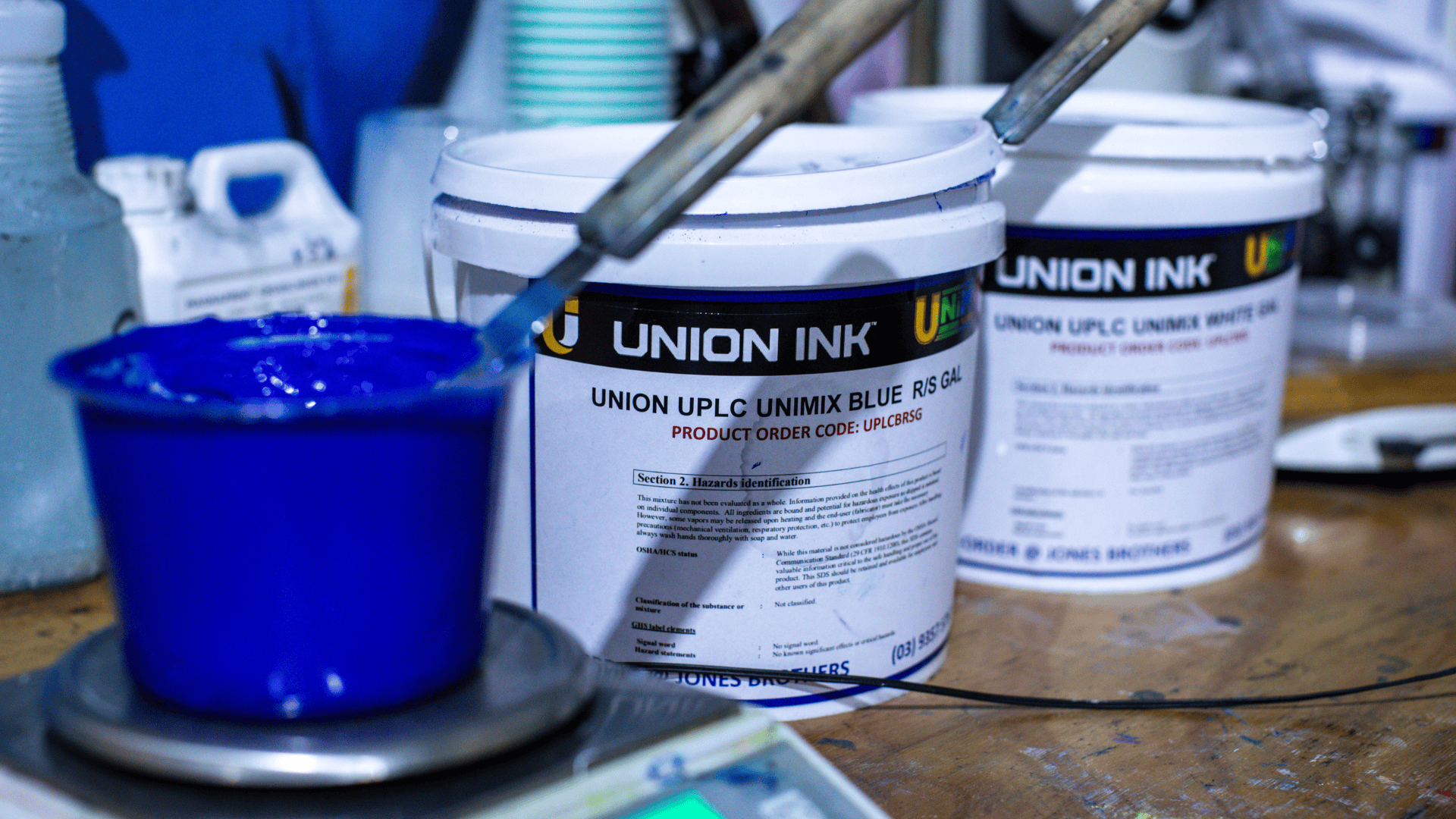

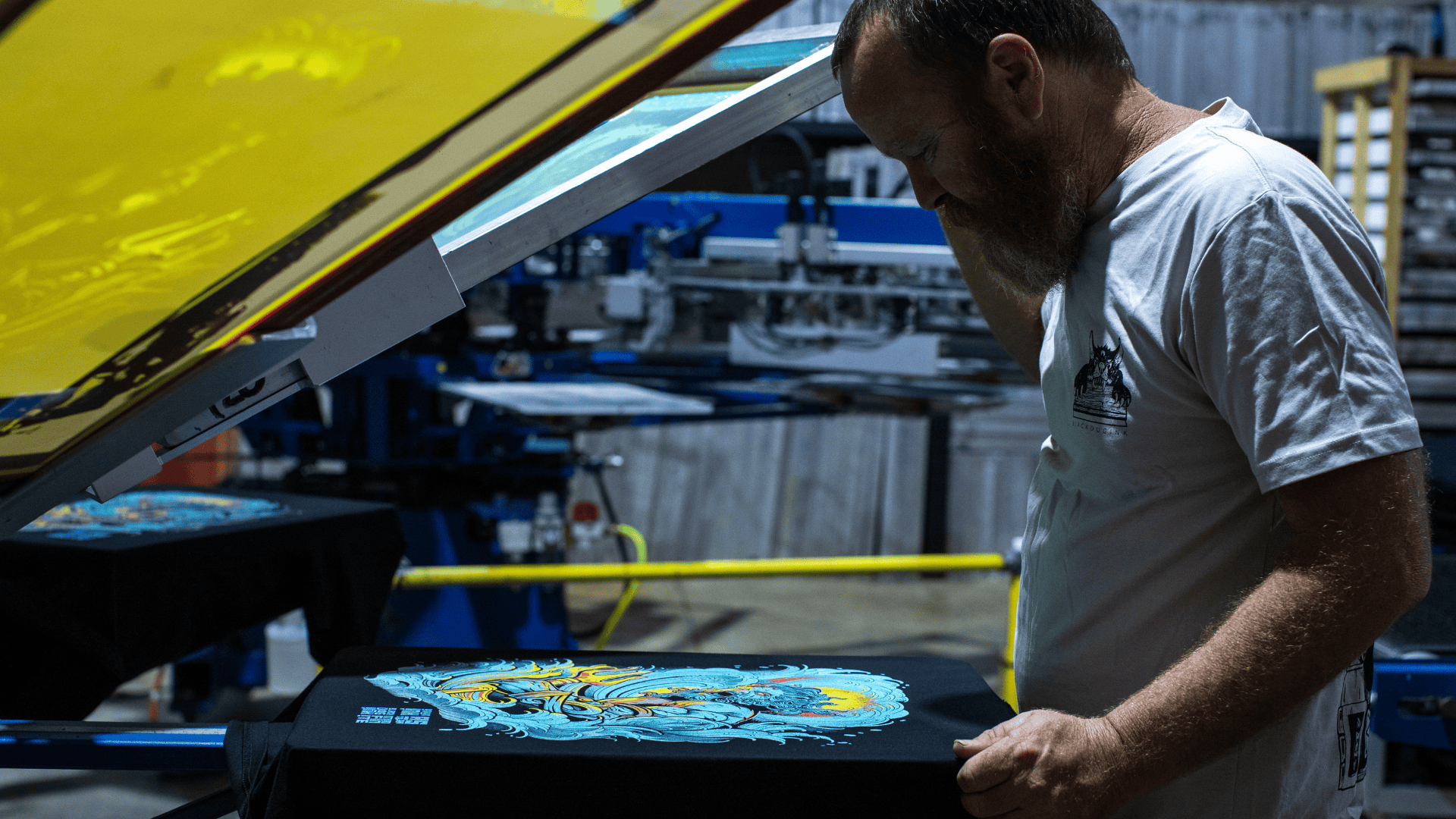

Mixing Union Ink UPLC UNIMIX colours in the BlackDog Ink studio.

Chapter 1: First Contact — “A Delight to Work With”

From the first stir, BlackDog Ink noticed something different. Most mixing systems require elbow grease — UNIMIX didn’t.

Key Observations:

- Creamy straight from the pot

- No tarry or gluggy behaviour

- Strong pigment load

- Reds & yellows more vibrant than expected

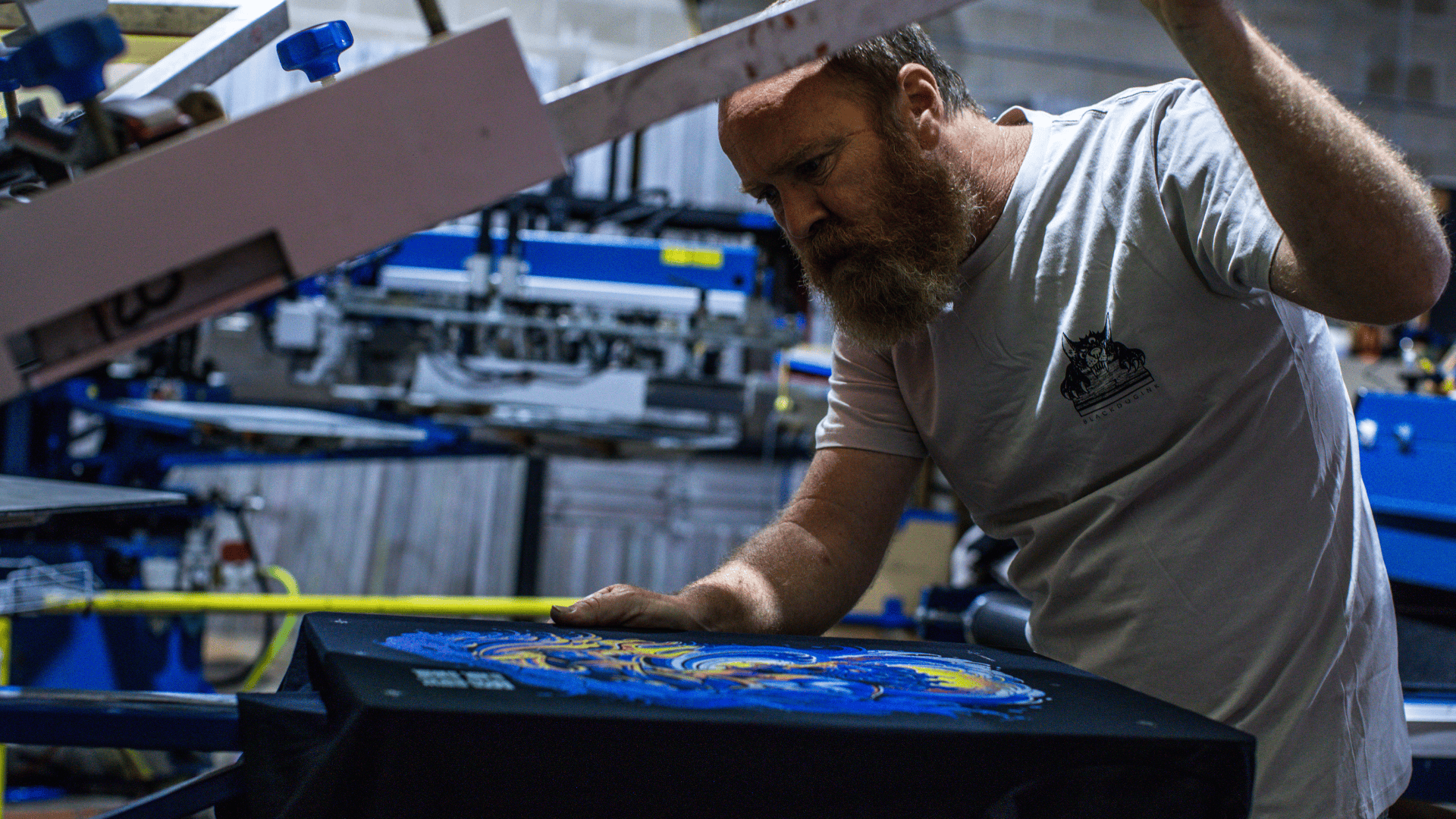

Chapter 2: Print Floor Performance — Consistency That Doesn’t Quit

Under production heat and pressure, UNIMIX stayed consistent — no thickening, no drying, no surprises.

- Excellent mesh ejection

- Clean stencil release

- Effortlessly passed through 100T + 120T

- Perfect wet-on-wet behaviour

Chapter 3: Colour on Polar White — “Brighter Than You’d Expect”

Polar White didn’t appear extremely opaque — but UNIMIX top colours exploded with brightness anyway.

- No chalkiness

- No tonal dullness

- Bright, punchy colours

- Excellent wet-on-wet performance

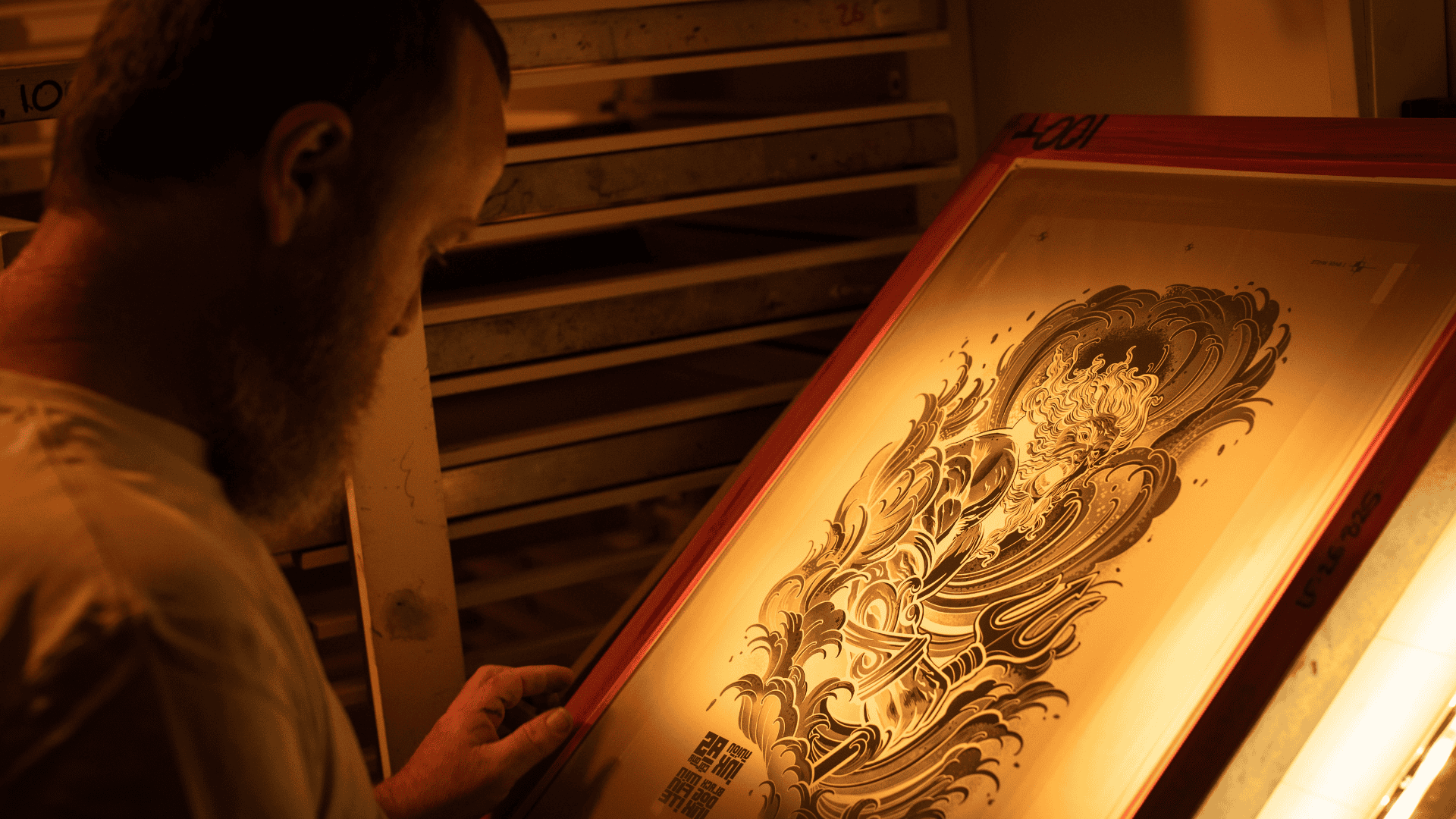

Managing flash timing and temperature for consistency.

Chapter 4: Flash & Cure Behaviour — Precision Required

Polar White must be flashed precisely — too hot and it holds heat; flashed correctly, it’s perfect.

- “Low & slow” curing works best

- Exit temp: 135–150°C

- No bubbling unless pushed over 160°C

Cleanup was fast and effortless thanks to UNIMIX’s clean-clearing behaviour.

Chapter 5: Clean-Up — The Unexpected Bonus

Despite strong pigments, UNIMIX cleaned up quickly with no aggressive scrubbing required.

- Easy reclaiming

- No unusual residue

- Fast cleanup times

Final prints showing the full power of UNIMIX pigments over Polar White.

Notes from the Artist

Artwork by Minnie Longstaff (@minfinite_ on Instagram)

The process of producing the artwork

I was really excited by the brief for this illustration. I started with a loose sketch to get the placement, pose & flow of the design roughly where I wanted them. When I was happy with that I went in and built up the forms and outlines.

I’m always mindful of how my designs will translate to screen for print and I like to make sure that you can easily see the main elements of a design even from a distance. My method for achieving this is to use bold lines and contrasting colours.

Composition is also super important in a design like this – I wanted to make Poseidon feel truly larger than life and really capture a sense of movement and power.

Thoughts on the final print

Mez (Chris) is a wizard! The print came out really close to the original illustration. All the little details and textures held up, and the motion still feels well and truly alive.

It always blows me away how Mez is able to achieve prints like this with such depth and saturation while still keeping the print nice and soft to wear.

Thoughts on the colours of the print

I put a lot of time into balancing the palette. I chose the cooler blues and teals to push the depth of the water, and then I used the warmer oranges to create a focal point around Poseidon and the trident without overwhelming the rest of the piece.

I really love to create that contrast and temperature. Getting those relationships right took some trial and error but the end result was totally worth it!

Conclusion: UNIMIX Proves Itself

Project Poseidon validated UNIMIX as a full-production mixing system capable of reliable, high-volume output.

Print Parameters

Printed 100% manually, wet-on-wet, proving UNIMIX’s stability even without auto-press support.

| Colour | Mesh | Method |

|---|---|---|

| Base White | 100T | Wet on wet |

| Yellow 3945C | 120T | Wet on wet |

| Red 1788C | 120T | Wet on wet |

| Cyan 319C | 120T | Wet on wet |

| Blue 286C | 120T | Wet on wet |

| Black | 120T | Wet on wet |

| Highlight White | 100T | Wet on wet |

Want to use UNIMIX in your shop? info@jonespt.com.au

APPRECIATIONS

This project was made possible by the amazing collaborative partners. Thank you to Elijah and the team at AS Colour, Chris & Erin from BlackDog Ink and the team at Union Ink.

The incredible artwork was completed by Minnie Longstaff

Amazing project photos and videos of the printing of the Polar White Project hoodie by Brad Collins.

FAQ

have A QUESTION?

HOURS

Monday to Friday

8:00 AM – 4:30 PM

Feel free to reach out during these hours!

PH: +613 9357 5767

E: info@jonespt.com.au

IG: @jonesptaus

HOW TO ORDER?

- To place an order, customers must send an email to info@jonespt.com.au

or send a DM via Instagram (@jonesptaus) with the details of the

items you wish to purchase. - Orders are subject to availability, and stock is limited. Orders will be

confirmed by a member of our team. - Orders are not finalized until confirmation has been sent from our customer

service team.

SHIPPING & Delivery

Shipping costs can be influenced by several key factors:

- Location: Shipping to rural or remote areas tends to be more expensive compared to metropolitan regions.

- Order Size: Larger orders often result in higher shipping costs due to weight and packaging requirements.

- Hazardous Goods: Certain products, classified as dangerous goods, require special handling and regulations, which increase shipping costs.

We strive to provide you with the most affordable shipping options, ensuring that your costs are minimized while maintaining safe and timely deliveries.