Description

Vynaglaze APR 47-00 Series – High Gloss Screen Inks for Plastic and Outdoor Applications

The Vynaglaze APR 47-00 Series is a high-performance screen ink system formulated for premium adhesion, flexibility, and gloss on a wide range of plastic materials. With exceptional resistance to weather, petrol, and alcohol, these inks are ideal for demanding indoor and outdoor applications such as window stickers, vehicle markings, labels, and signage.

Vynaglaze APR inks provide strong intercoat adhesion, high definition, and minimal blocking—even in multi-layered, double-sided prints. Their excellent flexibility makes them suitable for applications that involve forming, including vacuum and drape moulding.

Key Benefits:

- High gloss finish with fast drying and blocking resistance

- Exceptional flexibility for single or double-sided prints

- Excellent adhesion on rigid and flexible PVCs, acrylics, polycarbonate, and treated polyester

- Outstanding resistance to alcohol, petrol, and weathering

- Suitable for vacuum and drape forming

Recommended Substrates:

- Self-adhesive PVC films

- Rigid and flexible PVC sheets

- Acrylic sheet and polycarbonate

- Treated polyester films

Recommended Emulsions:

For optimal stencil durability and performance with Vynaglaze inks, we recommend:

- Murakami SR

- Chromaline UDC ACE

- Saati SAATIGRAF HS3

- Saati Grafic HU

Explore our full range in the Solvent & UV Emulsions collection.

Screen Setup:

- Mesh: 90–120 threads/cm recommended

- Stencil: Solvent-resistant emulsion

Drying:

Fast drying via jet dryers or rack drying. Additions of retarder will slow drying, so ensure proper air movement and temperature to maintain performance.

Coverage:

Up to 50 m²/kg, depending on mesh, stencil, and thinning.

Outdoor Durability:

Up to 5 years for standard colours, 7 years for XL colours, and 3 years for process inks under middle European climate conditions. No overprint varnish required. Durability may vary with ink reduction, tint strength, and local conditions.

Forming:

Suitable for vacuum and drape moulding. Not recommended for plug or die-assisted moulding where the tool may contact the ink film.

Ink Adjustment:

- Slow Thinner TS16: Up to 40% for high-speed printing

- Retarder TS17: 15–30% for semi-auto or hand work

- Slow Retarder TS11: For hot environments and press stability

- TS15/TS23: For polycarbonate substrates

Clean-Up:

Use AGM Green Citrus Wash or AGM Green Eco Wash for effective, eco-conscious screen cleaning.

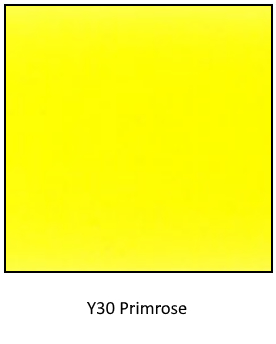

Colour Range:

Available in 16 standard opaque colours, 9 mono-pigmented Sunmatch mixing shades, XL weather-resistant colours, metallics, and process inks. Pantone®-validated formulations also available.

Storage:

Store in sealed metal containers at 5–30°C. Shelf life of up to 2 years under recommended conditions (excluding metallics).

Safety:

Refer to the Material Data Sheet (MSDS) for handling. Vynaglaze APR inks are formulated to comply with EN71 but are not routinely tested for children’s products or food contact surfaces.

For more information on this product, find the technical data sheet here.

Reviews

There are no reviews yet.