Description

Urocure Ink System – Two-Pack Urethane Ink for Glass, Metal & High-Performance Surfaces

Urocure is a premium two-part urethane screen printing ink system engineered for outstanding adhesion, chemical resistance, and weather durability across a wide range of industrial substrates. It’s ideal for demanding applications on non-porous surfaces like glass, ceramics, metals, and thermo-setting plastics.

Once catalysed, Urocure prints offer long-term resistance to hydrocarbons and harsh solvents, making them well-suited to industrial and high-contact applications.

Key Benefits:

- Exceptional adhesion to glass, ceramics, metals, and rigid plastics

- High gloss finish with excellent weather and chemical resistance

- Touch dry in 30 minutes; full cure in 7 days (or bake at 120°C for 30 minutes)

- Compatible with multicolour jobs using single post-cure or air drying

- Good screen stability and long pot life (24+ hours)

Mix Ratio & Curing:

Mix 80% Part A (ink) with 20% FUT176 Catalyst (Part B) by weight. Touch dry in ~30 minutes. For full cure, allow 7 days air drying or bake at 120°C for 30 minutes. No need to bake each colour separately in multicolour prints.

Recommended Emulsions:

To ensure superior stencil performance and solvent resistance with Urocure inks, we recommend:

- Murakami SR

- Chromaline UDC ACE

- Saati SAATIGRAF HS3

- Saati Grafic HU

Explore these options in our Solvent & UV Emulsions collection.

Thinning & Additives:

- Thin with up to 10% FUT180 Thinner

- Use FUT182 Retarder to slow drying in hot climates

- Add up to 10% FSU178 Sharp Print Compound for better detail

Recommended Substrates:

- Glass, ceramics, and coated metals

- Thermo-setting plastics and heat-resistant surfaces

Ensure surfaces are cleaned thoroughly with alcohol to prevent craters or crawling during printing.

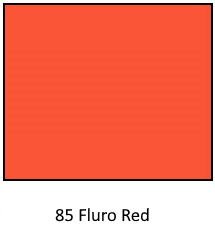

Colour Range:

Available in 9 standard colours, 8 Pantone base shades, black, white, and custom colours on request. Lightfastness rated Excellent to Good depending on shade.

Coverage:

Approximately 55 m² per kg, depending on mesh, thinning, and substrate.

Important Notes:

Due to the diversity of end-use requirements, users are responsible for testing for adhesion, chemical resistance, and durability before production. Refer to MSDS for both Parts A and B prior to use.

For more information on this product, find the technical data sheet here.

Reviews

There are no reviews yet.