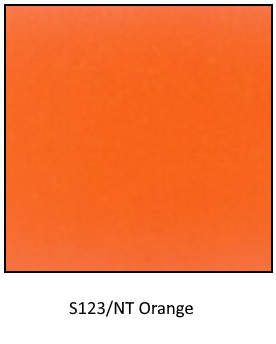

Description

Uni-PU 161-00 Series – Two-Pack Screen Ink for PU, PVC & Synthetic Leathers

The Uni-PU 161-00 Series is a high-performance, two-component polyurethane screen ink system designed for exceptional adhesion, flexibility, and wear resistance on synthetic leather and coated substrates. Formulated for durability and vibrant finishes, it is ideal for printing on tote bags, PU/PVC leathers, and various synthetic products.

This solvent-based ink features excellent rub and solvent resistance, a glossy finish, and the ability to air-dry or cure faster in heat-assisted systems.

Key Benefits:

- Two-component ink system with catalyst for enhanced durability

- Excellent adhesion and flexibility on synthetic surfaces

- High gloss finish with strong rub and solvent resistance

- Can air-dry (30–60 min) or cure in 2–3 minutes at 70–80°C

- Great opacity and suitability for both fine detail and high-coverage prints

Recommended Applications:

- PU and PVC leather

- TOU and coated leathers

- Tote bags and synthetic materials

Always pre-test for compatibility with your specific substrate.

Recommended Emulsions:

To ensure solvent durability and sharp detail when using Uni-PU inks, we recommend the following solvent-compatible emulsions:

- Murakami SR

- Chromaline UDC ACE

- Saati SAATIGRAF HS3

- Saati Grafic HU

Explore these in our Solvent & UV Emulsions collection.

Mixing & Pot Life:

Catalyse with 10% Uni-PU Catalyst 161-C191. Once mixed, pot life is 8–12 hours depending on ambient conditions. Stir well and thin with 10–20% of either 161-T102 (fast reducer) or 161-T104 (normal reducer).

Drying & Curing:

Air dries in 30–60 minutes, fully cures in 24 hours at room temperature. Jet drying at 70–80°C reduces cure time to 2–3 minutes.

Screen Printing Setup:

- Use 120 threads/cm mesh for fine details; 21 threads/cm for high opacity

- Solvent-resistant stencils required

- Recommended squeegee hardness: 70–75 Shore

Available Colours:

Full SSI colour guide range, including process colours and bases. Includes extender medium (161-185), metallic base (161-D100), and catalyst (161-C191).

Storage & Safety:

Shelf life approx. 12 months at 25°C. Store in a cool area and use standard hygiene practices during handling. Refer to SDS for safety instructions.

For more information on this product, find the technical data sheet here.

Reviews

There are no reviews yet.