Description

Rebuild with Precision — Powered by SAATI Mesh Technology

When it comes to screen performance, the mesh is everything. Our professional remeshing service pairs expert craftsmanship with world-class mesh from SAATI — the benchmark in premium screenprinting fabrics.

We remesh with:

🔹 SAATI HI-R® Mesh

A premium, high-modulus monofilament polyester mesh designed for exceptional tension stability and stencil adhesion. Ideal for shops running detailed graphics, halftones, or high-volume runs.

Key Benefits:

-

Superior tension retention and low elongation for consistent performance

-

Increased stencil durability and longer print runs

-

Faster exposure times and excellent definition of halftones and fine lines

-

Surface modified via atmospheric plasma, eliminating the need for degreasing and enhancing adhesion across all emulsion types

-

Performs flawlessly with Photopolymer, Dual-Cure, and Diazo emulsions

🔹 SAATI HI-DRO® Mesh

Engineered specifically for water-based and discharge ink printing, HI-DRO offers optimized ink flow and superior coverage — even on dark garments.

Key Benefits:

-

Thinner thread diameters and optimized mesh geometry for higher open area

-

Enhanced ink flow and coverage, reducing flashing and improving opacity

-

Plasma-treated surface offers exceptional stencil adhesion and eliminates degreasing

-

Ideal for abrasive inks and pastes in demanding print conditions

-

Compatible with all emulsion systems, including capillary film

🔧 Our Remeshing Process:

-

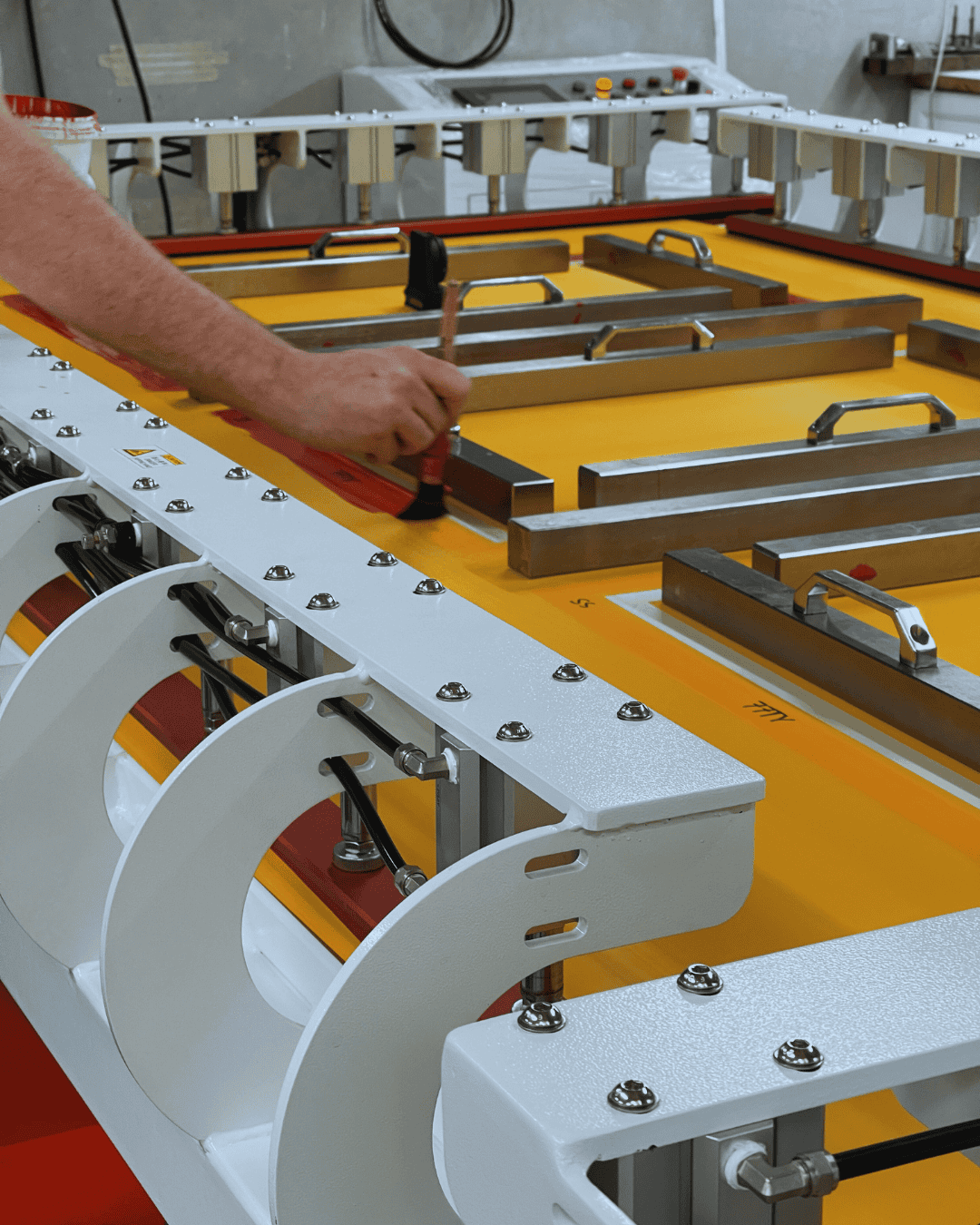

Precision-tensioned using pneumatic clamps and calibrated tension meters

-

Frame inspection, cleaning, and abrasive grinding for superior glue bonding

-

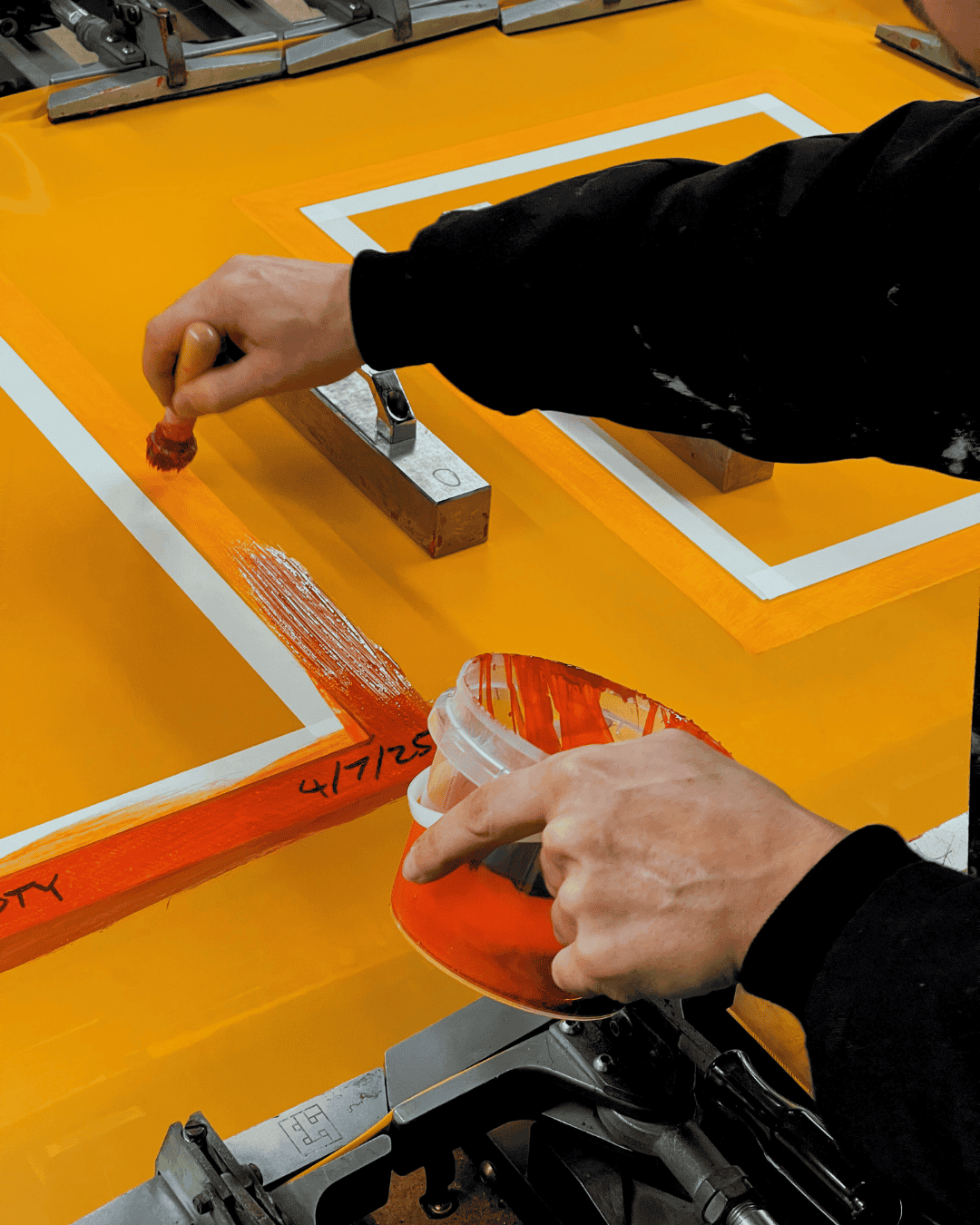

Industrial-grade adhesive application and optional frame reinforcement

-

Tension verified for each screen and labelled for tracking (if requested)

With the right mesh, your screens become more than tools — they become assets. Partner with us and experience remeshed screens that perform like new, built on the backbone of SAATI’s cutting-edge textile science.