Description

Gloss Polycat 56-00 Series – High Gloss Two-Pack Ink for Polyethylene & Polypropylene Containers

The Gloss Polycat 56-00 Series is a two-pack solvent-based screen printing ink system designed for high-performance decoration of treated polyethylene and polypropylene containers. Engineered for maximum adhesion, chemical resistance, and visual impact, Gloss Polycat inks are ideal for cosmetic, personal care, and household product packaging.

These inks deliver a brilliant gloss finish and are formulated to resist a wide variety of oils, detergents, and other challenging products. With a fast drying profile and excellent press stability, they are well-suited for both manual and automatic high-speed bottle printing.

Key Benefits:

- Outstanding adhesion on flame-treated polyethylene and polypropylene

- High gloss finish with strong product resistance

- Excellent intercoat adhesion and overprint compatibility

- Quick drying: handleable in 1–2 minutes at 80–85°C

- Air dries to a fully cured film within 3–4 days if oven cure is unavailable

Substrate Requirements:

Designed for flame-treated polyethylene and polypropylene. Flame treatment must meet optimal wetting tension (testable via Union Carbide Wetting Tension Pens) for proper adhesion. Re-treatment between colours is not recommended.

Mixing & Usage:

Mix 9 parts pigmented paste to 1 part catalyst varnish by weight. Mixture is usable for up to 24 hours if sealed. White 56-81 should be mixed 15:1 for overprinting purposes. Thin up to 15% with TS23 for high-speed bottle printing.

Printing & Drying:

- Mesh: 80–120 threads/cm (fine nylon or polyester)

- Squeegee: Medium to hard with sharp edge

- Stencil: High-quality solvent-resistant emulsion (e.g. Coatazol Panorama, Murakami One Pot Sol)

Drying: 1–2 minutes at 80–85°C for handling; fully cured in 3–4 days. Can also air dry at room temperature or be hot air dried.

Coverage:

Up to 50 m²/kg depending on mesh, stencil, and print conditions.

Colour Range:

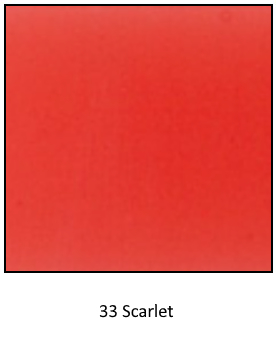

Wide selection of mono-pigmented bright colours, including High Opacity Yellow, Red, Orange, and White. Available via Coates

Reviews

There are no reviews yet.