In the screenprinting industry, creating flawless prints requires thorough preparation of your screen mesh, especially before you expose your next stencil. One essential aspect of this preparation is the removal of stains and haze that build up over time. In this blog, we’ll explore what haze is, how it impacts your screens and future prints, and the best methods to remove it effectively.

What is Haze, and Why Does It Matter?

Haze is the residue left behind on your screen mesh even after the ink and emulsion have been cleaned off. It often appears as faint, ghostly images or shadows from the previous print. This build up can include remnants of plastisol inks, UV-curable inks, and even photo emulsion coatings that were not fully removed. It tends to accumulate in the mesh knuckles, where the threads overlap, making it difficult to remove with a simple wash.

The leftover haze, if not addressed, can have several negative effects on the quality of your prints:

Inconsistent Stencil Exposure: When a new emulsion is applied, the presence of haze can affect the exposure process. Residual stains block light from passing through, resulting in uneven exposure. This may lead to incomplete or damaged stencils that will fail during the printing process.

Poor Print Quality: Haze can lead to unintended texture or ghost images appearing on your new prints. This can compromise the clarity of fine details and colors, making it impossible to achieve a perfect finish. Residual ink can also interfere with color accuracy, leading to off-hue prints.

Reduced Screen Life: Leaving haze untreated can reduce the lifespan of your screens. Over time, the buildup will become harder to remove, potentially damaging the mesh when aggressive cleaning methods are used. Proper maintenance is key to ensuring your screens perform well over many production cycles.

The Effect of Stains and Haze on Future Prints

Imagine printing a vivid yellow design only to discover that faint shadows of a previous black ink job have bled through—this is a result of inadequate haze removal. Stains interfere with the ability of the new ink to adhere evenly to the screen, leading to imperfections in the final product. Particularly when switching between light and dark inks, any residue left on the screen can drastically affect the next print’s color and detail, creating an undesirable “ghost” effect.

Furthermore, haze affects your control over ink flow through the mesh, causing potential blockages or inconsistent ink deposits. These inconsistencies make it challenging to achieve uniformity in multi-color designs, leading to a lot of wasted time, material, and money.

Best Practices for Removing Haze

To maintain your screens in peak condition and ensure quality prints, it’s vital to follow an effective cleaning routine. Here are some steps and products recommended for removing haze effectively:

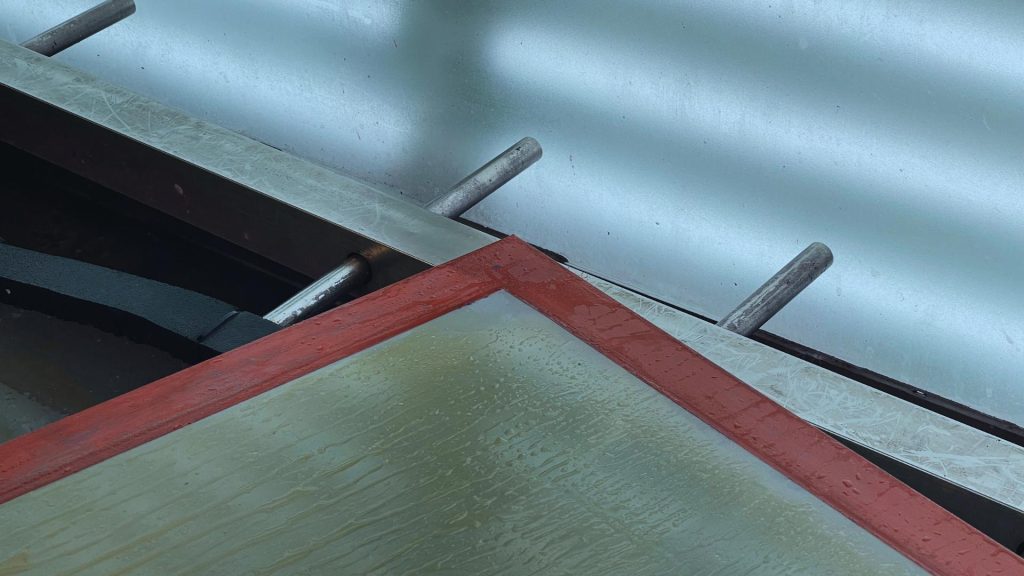

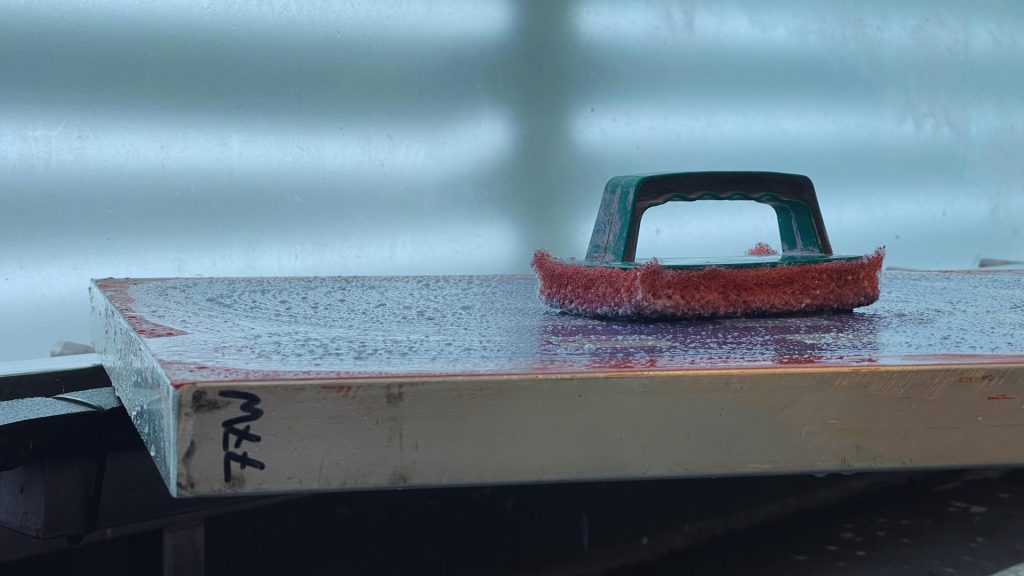

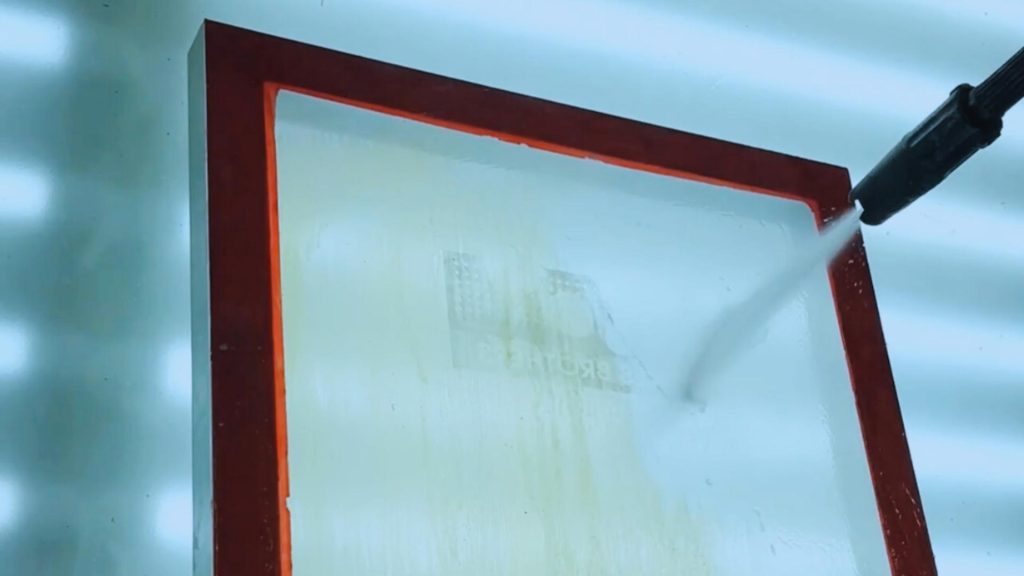

Use a Specialized Haze Remover: Products that are specifically formulated to target stains and haze on screen mesh. This eco-friendly stain and haze remover is highly effective at dissolving ink residues from previous print jobs, ensuring your screens are ready for their next use. Apply the remover to both sides of the screen, scrub in circular motions, and allow the solution to sit before rinsing with a pressure washer.

Deep Cleaning with Screen Reclaimers: Once the initial ink and emulsion are removed, use a high quality screen reclaimer/emulsion remover/stencil remover to reclaim the screen fully. Scrubbing with a nylon brush and using a pressure washer helps in dissolving any remaining stencil residues, ensuring your screen is entirely clean and free of any ghost images.

Pressure Washing: After applying haze remover, use a pressure washer to fully dislodge any stubborn ink or emulsion residues. A high-pressure wash ensures that every part of the screen is thoroughly cleaned and that there is no leftover haze to affect future prints.

Conclusion: Make Haze Removal a Priority

Removing stains and haze from your screen mesh is not just an optional step—it’s essential for maintaining the integrity of your stencils and achieving high-quality prints. Haze and ghost images affect everything from color accuracy to stencil durability, and they can even decrease the lifespan of your screens if left untreated.

By integrating specialized haze removers like AGM Pink Demon and following a consistent reclaiming process, you can keep your screens in excellent condition. Not only will this improve the quality of your prints, but it will also help you achieve a more efficient workflow, saving you time and resources in the long run.

Whether you’re a small shop or a large production facility, investing the time to properly remove haze is an investment in the quality and consistency of your screenprinting projects