If your coated screens aren’t performing like they used to — or if you’re battling issues like sticky emulsion, weak stencils, or uneven exposure — the culprit might not be your technique or your emulsion.

It might be your air.

Humidity is one of the most overlooked variables in a screenprinter’s darkroom, and it can quietly wreak havoc on your coated screens and overall stencil quality. Here’s why it matters and how to fix it.

💧 Why Humidity Matters in Screen Coating

Screen emulsions — especially dual-cure and SBQ photopolymers — are sensitive to their environment. Once a screen is coated, it needs to dry in a controlled space. If the surrounding air contains too much moisture, it can affect how the emulsion sets and bonds to the mesh.

What happens when humidity is too high?

Emulsion remains soft or tacky, even after extended drying times

Pinholes, fish eyes, or surface defects appear during coating or drying

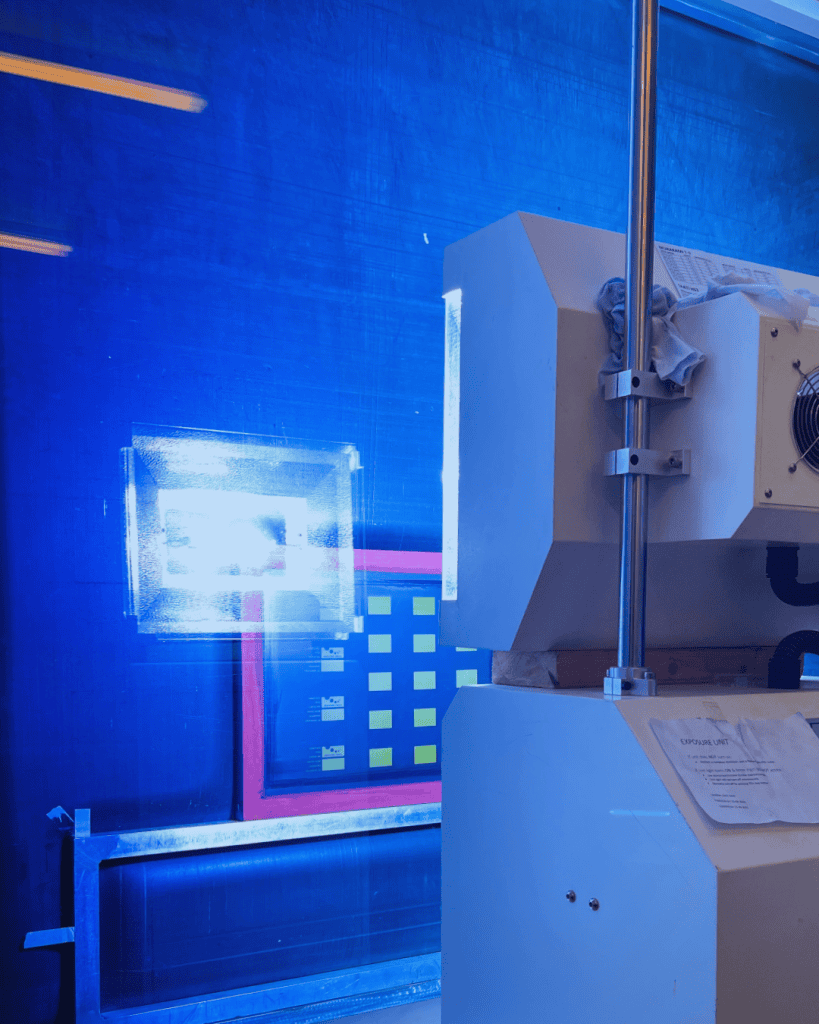

Incomplete exposure, due to inconsistent emulsion thickness

Stencils break down prematurely, especially with water-based or discharge inks

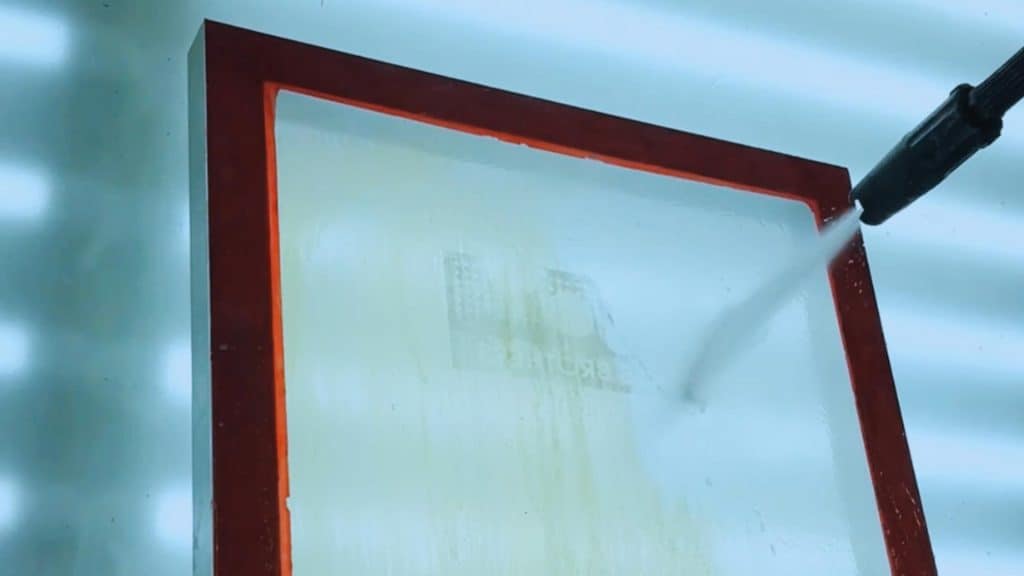

🚿 How Your Washout Area Might Be Making It Worse

Even if you’ve got solid airflow and your room feels “normal,” the source of the problem could be right next door: your washout booth.

If your washout area shares space with your darkroom — or if there’s poor airflow between the two — every use of cold or hot water releases moisture and/or steam into the air. That moisture will hang in the atmosphere and cling on to uncoated and coated screens.

What makes it worse:

Lack of ventilation

Using warm/hot water

Poor separation between washout and darkroom zones

🌫️ The Effects on Emulsion Stability

When moisture remains in or around the emulsion layer:

Drying takes longer, increasing the risk of contamination

The emulsion fails to bond fully to the mesh, leading to stencil lifting

Exposure light is scattered, creating blurry or undercured artwork

Storage life of coated screens drops significantly

It’s not just a minor inconvenience — it’s a recipe for inconsistent results, wasted time, and failed prints.

📉 The Ideal Conditions for Drying Emulsion

To ensure consistency and stability, your darkroom should maintain:

Temperature: 20°C to 25°C

Humidity: 30% to 50% relative humidity

Airflow: Constant, clean, filtered airflow without drafts or dust

These conditions support optimal emulsion drying and preserve stencil integrity until you’re ready to expose.

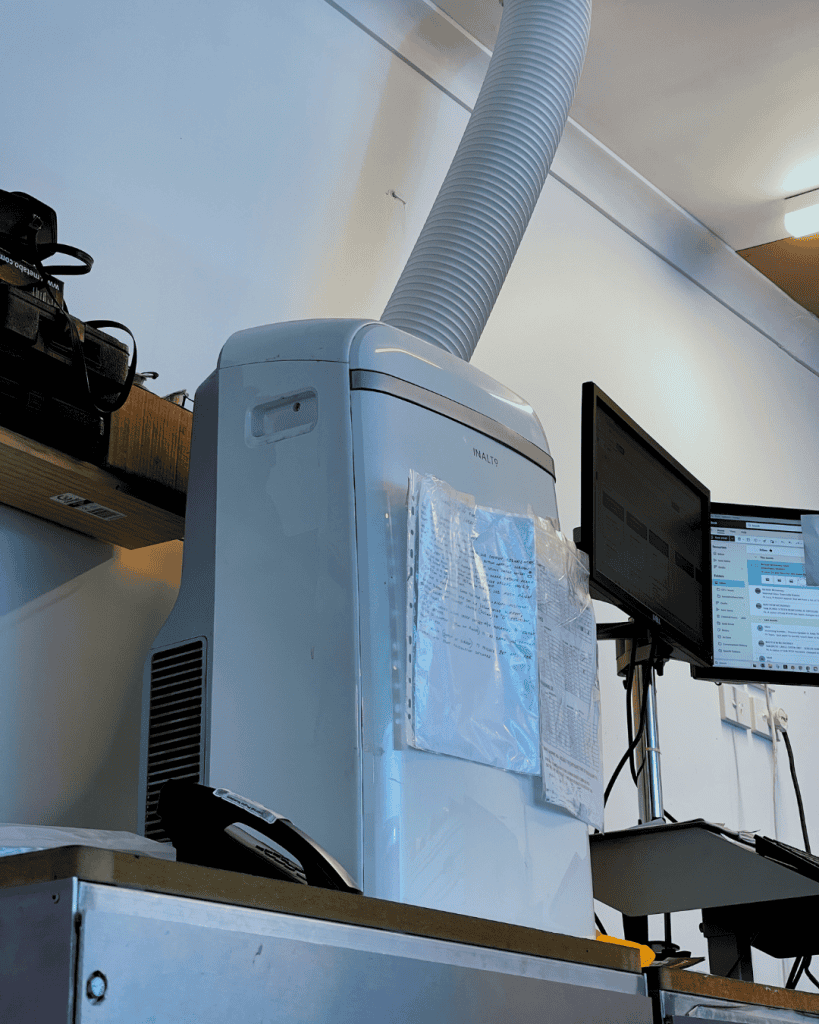

⚙️ The Simple Solution: Add a Dehumidifier

A reliable dehumidifier is a game-changer for any screen room. It ensures your space stays in the ideal humidity range, regardless of seasonal or environmental changes.

Benefits of using a dehumidifier:

Keeps emulsion tack-free and smooth during drying

Promotes even coating and consistent stencil thickness

Extends shelf life of coated screens

Reduces risk of pinholes and underexposure

If you’ve got issues with stencil durability or screen coating consistency — especially in the cooler, wetter months — this might be the upgrade your workflow needs.

🧼 Final Thoughts

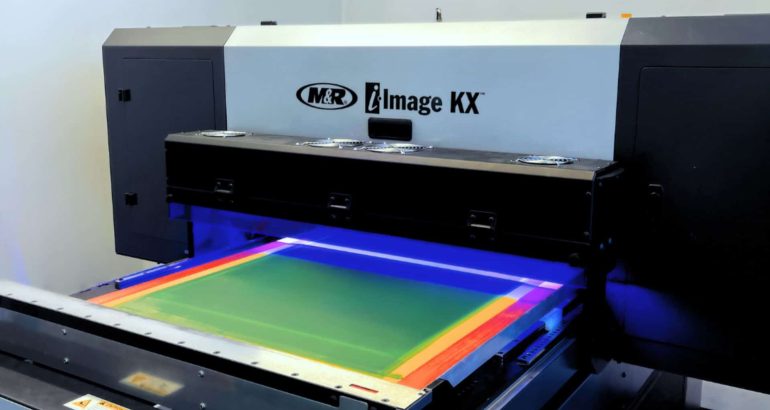

Great stencils start before the exposure unit. They start with a clean, controlled drying environment.

Humidity might be invisible, but its effects are not. Invest in managing your darkroom climate and you’ll see clearer detail, stronger stencils, and far fewer production issues.

Moisture out. Quality in.