In this edition of Behind the Mesh, we sit down with George Hassan—owner, printer, and the driving force behind Phantom Printing on the Gold Coast. With nearly three decades in the industry, George’s journey has taken him from scrubbing screens in a Christchurch print shop to managing Australia’s biggest print floors and building his own high-output operation from the ground up.

Known for his sharp eye, relentless work ethic, and passion for all things mechanical (with a bit of Bogan flair), George shares insights on surviving the print game, pushing boundaries with process work, and the real lessons he’s learned from both triumph and adversity.

Keep up to date with Phantom Printing

Instagram: @phantomprinting

About George

List 3 things about yourself – fun facts, hobbies, pets or interests

- I am from Christchurch, NZ and been printing for 28 years and counting I moved to the gold coast for printing in 2009.

- I live on the Gold Coast on waterfront property where I jet ski before work if the tides right.

- I have 4 kids, 2 step children, 4 Chihuahuas and 3 Sphynx cats

- True Bogan at heart, I love fast cars, tattoos, design, anything mechanical.

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

Where It All Started

I kicked off my screen printing journey in 1997 at a shop in NZ, scrubbing screens with a turps bath and a brush—courtesy of a family friend from the pub. By 10am smoko, I was half-floated off the fumes. But that’s where it all began.

In the early days, I specialised in advanced screen making—working with 120T mesh on 3×3 metre screens using a scissor lift for sublimation printing. I printed sportswear for Adidas and Canterbury, back when full garment manufacturing was in-house, from yarn knitting to transfer printing for export. We developed adhesives and anti-migration solutions long before they were industry standard—25 years ago, this was cutting-edge stuff.

Mastering the Craft

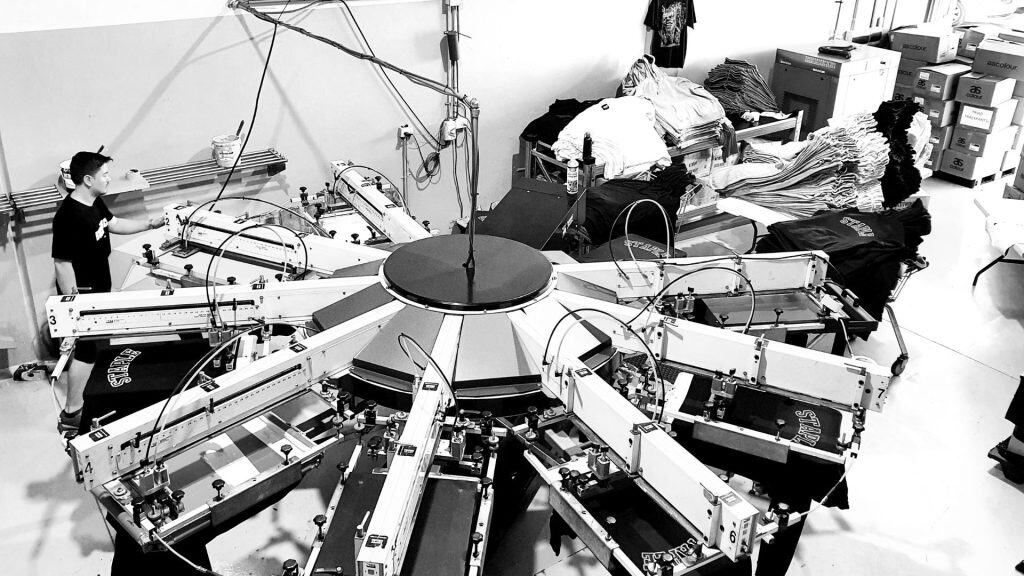

I spent years hand-printing on manual carousels, then moved into automatics in 2002. I’ve owned eight autos and operated over 27 machines. Back then, TAS and M&R ruled the game, and I was printing massive volumes—35,000 garments in a week at one point. With over a decade of experience in high-volume work, I moved to Australia in 2009 for a role in Burleigh Heads. It was a culture shock—from a white-collar print shop in NZ to a hardcore, plastisol-heavy setup—but I adapted fast.

I went on to manage one of the largest print shops in Australia, scaling from 2 to 6 autos (TAS and M&R). We pushed limits with 12-colour simulated process prints and even won a Golden Image Award in LA for discharge work. That trip opened my eyes—visiting shops with 50+ autos showed me what was possible.

Building Phantom

These experiences paved the way for Phantom Printing. I started in a single-car garage, printing until 2am with a 6-colour manual, curing water-based inks in a microwave. I’ve printed NRL jerseys for Nike using HD gels I developed and exposed 400+ EOM stencils with a homemade UV bulb.

Eventually, I was given a factory and capital by someone who believed in me. Phantom grew from there. My head printer Caden’s been with me from day one—he knows every trick in the book. That team-first mindset has been everything.

Today, we specialise in 9–12 colour simulated process prints on Newman Roller frames stretched in-house to the highest mesh tensions in the country. We offer training and consulting alongside our production. We only use the best—AS Colour garments and Jones Brothers inks and consumables.

Hard Lessons & Hard Work

I’ve also learned the hard way. I built a shop in 2012 with a partner who took everything. I walked away with a flash cure and some screens. Years later, my ex-wife took my fully engineered two-level factory, along with a mortgage-free home—all built through printing. It cost me over $150K just to relocate and start again.

Despite it all, printing has always been my anchor. In tough times, it’s kept me focused and out of trouble. I’ve seen great printers lose everything not from lack of skill, but because of the people around them. So be careful who you marry, partner with, or let ride shotgun in your business.

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

There’ve been a few standout projects over the years, so I’ll list a couple—but at the end of the day, it all comes down to personal preference and what you enjoy most.

One of the more unique jobs was printing the costumes for the Aquaman movie, which was filmed right here on the Gold Coast. These were high-density raised prints with a foil kiss finish. I did them all by hand, using 1-metre alloy pallets and heat pressing rolls of foil over each panel. Each costume had more than 20 individual panels—and we completed over 60 full suits. The rate? An eye-watering $1,000 per costume.

Another highlight was printing the official Wallabies jerseys back in 2012. We used a high-density grip gel that I’d originally developed years earlier in my garage. The gel was printed in a specific pattern to help players get better grip on the ball—especially in wet conditions. I even travelled to China to research how plastisol and silicones were made and imported specific materials to bring that project to life.

What I took away from these jobs is simple: sometimes in screen printing, you have to think way outside the box. These weren’t your standard t-shirt runs—but they brought in significantly more revenue and pushed the craft in a completely different direction.

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

Before we dive into this, this is my opinion, let’s address the elephant in the room:

DTF and DTG aren’t screen printing.

Sure, a lot of shops are losing smaller, multicolour runs to these digital options, and yeah—they’ve made a mark on the industry. But let’s be real—as screen printers, we know it’s just not the same. That said, it’s important not to dismiss their impact entirely.

Will they ever beat screen printing? Not a chance. Even a million-dollar digital hybrid system can’t match the texture, durability, or cost-effectiveness of a well-executed screen print.

Everyone knows we love printing. I’ve always been about pushing the limits—whether it was discharge and foil back in the 2010s, or today’s oversized puff and distressed spot-process looks dominating retail. Trends come and go, but good print is timeless.

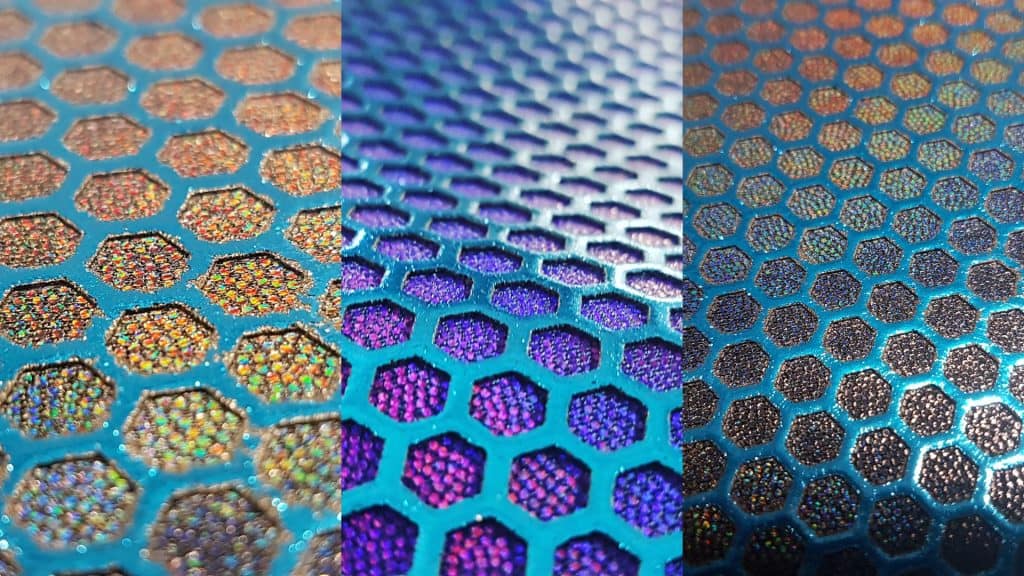

There’s nothing better than seeing a sharp, clean print pop up on Instagram—even a 2-colour job, if it’s executed well, deserves respect. We all start somewhere. I’ve always pushed our inks to their limits—whether it’s achieving a super opaque colour or layering metallics over razor-sharp underbases with no peak.

That’s the thing—trends will keep evolving, but the key is to be good at all of them. Don’t just chase production volume. Research, test, experiment. Build an R&D mindset into your shop culture. After 28 years in the game, I’m still learning new techniques and refining old ones.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

The social media scene for screen printing has really levelled up lately. It’s awesome to see so many talented young printers sharing clever, creative content—and even a few industry veterans bringing back some old-school prints and gear. We love seeing it all.

That said, one of the challenges we face is when we post our clients’ work online and they get approached by other printers. But here’s the thing—we know the difference. The reality is, they’re just not producing the same quality. No shade, just facts.

Looking ahead, we’re planning to share more informative content over the next few months—spotlighting the products and tools we rely on and think more people should be using too.

Shop Floor

What is your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

Jeepers—well, I’m not as much of a hoarder as I used to be, but over the years I’ve held onto some pretty special machines with serious history behind them.

Of course, we wouldn’t be where we are today without our Australian-built TAS 16-colour press. She runs every single day, and when we look at the prints coming off her, we’re confident in saying this: no new tech—whether it’s a million-dollar digital printer or the latest flashy auto—comes close. Sure, everything prints, but this is screen printing, and we believe in supporting Australian manufacturing wherever we can.

Now, if we’re talking prized possessions, my mantelpiece treasure is hands down a pallet knife I picked up from the Billabong print shop in Burleigh Heads. Growing up in NZ during the ’90s, everyone wanted a surfy Billabong tee—that was the dream. Mine was to one day leave NZ and go print for Billabong.

By the time I got there, it wasn’t to start printing—it was to close the shop down. As the equipment was being auctioned off, I managed to grab this pallet knife. I call it Excalibur.

That knife has been with me through it all—the highs, the lows, and everything in between. And as someone who’s been mastering plastisol ink for 28 years, Excalibur is more than just a tool. It’s a piece of my story.

What is on your wish list for your shop floor this year?

Honestly, my goal is simple—I just want to keep growing and moving forward. Like many others in our industry, I’ve faced a fair share of setbacks over the past few years. Between COVID and an unpredictable economy, it’s been tough to justify big investments in new equipment or expansion.

My genuine advice to other printers? Don’t overlook second-hand machinery. Before locking yourself into a $100K+ investment for a shiny new press, take a step back and really assess your numbers and workflow. In many cases, a quality pre-owned machine can do the job just as well—for a fraction of the cost.

If I had the space and the volume, I’d grab another TAS machine in a heartbeat. They’re built here in Australia, parts are available overnight, and the team is hands-on—whether your unit is brand new or has a few years under its belt. Plus, let’s be honest—TAS patented the tech. You’re getting a rock-solid machine without the fuss of flimsy imports.

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

Starting out in screen printing? You’ve got to be all in. This industry demands full commitment—late nights, early mornings, and a willingness to get your hands dirty.

There’s real opportunity out there, especially with so many shops having closed since COVID. But to last in this trade, you’ve got to respect it. Safety is critical—earmuffs, gloves, masks, and ventilation. I’ve damaged my hearing from washout booths and never go without earmuffs now.

Basic training gets you printing, but once you go deeper, the gaps show. There’s no plug-and-play guide for advanced printing—buying an auto doesn’t make you a pro. Most experienced printers don’t share much, but after 28 years, I’ve changed my mindset. At 43, I’m all about training and sharing—on-site and at our Gold Coast facility.

I’ve started from the ground up and seen first-hand how crucial training is. We’ve helped clients invest wisely, turning $300K setups into high-performing operations by focusing on workflow, quality, and staff development. Without proper guidance, shops struggle—many are hanging by a thread because staff don’t know how to run the gear.

Screen printing isn’t going away. Digital and DTF aren’t the same. So if you’re serious—get the gear, start printing, and learn fast. But don’t just focus on production. Build a team, train them well, and treat your business like a long-term career, not a sprint.

If you don’t, you’ll end up doing everything yourself—and that’s a fast road to burnout. I’ve been there—60-hour weeks and too exhausted to enjoy time with mates. Build it right, support your team, and the rest will follow.

Bonus

What’s your go-to playlist for a productive printing session?

Also rocking tunes in a print shop right! Big Genre here we are 50s to 2020 ish before music got weird.

Best Shop Beats:

Limp Bizkit 2000s Rock

We throw in a bit of Elvis and Ga Ga for good measure

But plenty of rock that’s the beauty of having your own shop, you can do what you like and plenty of flat singing apparently ha ha.

Conclusion

From printing high-density superhero suits to developing custom gel formulas in his garage, George Hassan is living proof that screen printing is as much about grit as it is about skill. Through setbacks, big wins, and late-night print runs, his commitment to the craft and community hasn’t wavered. Phantom Printing is more than a shop—it’s a blueprint for what’s possible when you combine experience, resilience, and a genuine love for the print.

Whether you’re just starting out or decades deep, George’s story is a reminder: this industry rewards those who stay curious, stay committed, and never stop learning.