What do a punk zine designer, cross-country road-tripper, and surf-shop kid have in common? They all exist in the story of John MaGee—a true lifer in the world of screen printing.

With roots in DIY culture and decades of hands-on experience, John has been pushing ink and boundaries since 1992. His journey has taken him from bootleg T-shirts on the side of the road to printing for iconic skateboard brands and top-tier bands.

Today, he’s the Senior Applications Development and Technical Service Representative at Avient Specialty Inks, where he continues to educate, innovate, and elevate shops across the industry.

John doesn’t just live and breathe screen printing—he builds it from the ground up (literally). In this interview, we get a glimpse behind the mesh into the lessons, laughs, and late nights that shaped one of the industry’s most trusted voices.

Let’s dive in.

Keep up with John on:

Instagram: @traveling_screenprinter

About John

List 3 things about yourself – fun facts, hobbies, pets or interests

- A Life in Transit

I’ve always travelled for some reason or other. When I was younger, my father was a traveling sales rep, and I would accompany him on the road, criss-crossing the American Southeast.

Later, in my early twenties, I would save my money all summer and then drive around exploring the Southwest and Pacific Coast—staying at hostels and couch surfing.

One year, after spending two months on the road, a friend and tattooer invited me to tour the East Coast and Midwest for another two months while he tattooed out of people’s houses. We often stayed at the homes of hardcore and punk bands. This led to me being invited to travel with bands as a merch guy or roadie.

Additionally, I was building a client base for my first screen print shop, which I would open in my mid-20s. I continued to travel whenever I could, exploring outside of the U.S.

So, when people comment that I’m on the road a lot, I just tell them—I’ve always had a traveling life in some way or other.

Now, at the age of 50, the airports and hotel rooms take a toll on me. However, when people ask how my family deals with my travel, I explain that most of my trips are only 2–3 nights.

After all, I met my wife on a 2-month nationwide band tour—she knew what she was getting into.

2. Built for Business

Most of the people in my family are self-employed, so I was raised to own a business. I’ve largely been self-employed most of my adult life before going to work for Rutland Group, which would eventually come to be owned by Avient.

I’ve owned two print shops, a skate shop, an indoor skatepark, and my wife and I owned an independent yarn brand—along with some other smaller ventures.

I’ve had a lot of people comment on how many things I’ve done and how many places I’ve lived and visited. I have to explain that while I’ve had a lot of acquaintances and several close friends, most of my time has been spent solo—allowing me a lot of time and energy to pursue my interests.

Later in life, after having a kid who would be diagnosed as high-functioning autistic, I too was diagnosed as being on the spectrum. I think this explains my obsessive interests and many hobbies.

On more than a few occasions, I’ve watched my employees leave for the day and then return the next morning to find that I had been working all night.

I’ve learned to manage this better and build better routines so that I get more regular sleep—but it’s still not unusual for me to go a couple of days without sleeping.

Thinking back on my days driving around the U.S., I can think of at least a half dozen times that I’ve driven for 24 hours or more. I LOVE a road trip.

3. From Surf Shops to Screen Shops

One of the key reasons I drove across the U.S. was because I grew up surfing the Florida coast and wanted to surf in California.

I used to work in a surf shop when I was 14, so board sports have always been a big part of my life—along with motorcycling and exploring the woods.

Really, any solo activity has appealed to me

In my first screen print shop, I had a couple of 1970s Land Rovers I was restoring, which earned me the nickname “Land Rover John”—which honestly is much better than “T-shirt John.”

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

Growing Up in a Side Hustle Family

From the late 1970s through the early ’90s, my parents always had some kind of side hustle going. When I was young, they’d set up a glass-blowing stand at malls, department stores, and local fairs. We sold everything from:

Glass figurines

Beaded necklaces

Velvet Elvis and Led Zeppelin plaques

Heat-pressed T-shirts

One summer, I remember my dad buying a trailer full of bootleg Michael Jackson and ZZ Top screen prints, which we sold roadside near the beach.

They even started an ad specialties company—printing matchbooks and creating ads for local businesses that were displayed in men’s bathrooms and gym lobbies. I was put to work early in all of these ventures, without realizing they were teaching me the foundations of “analog” graphic design.

Everything was done by hand—clip art books, rub-on foils, pasted layers—and the most high-tech tool we had was a small photocopier.

Punk Rock, Zines, and Early Design Roots

In high school, the kid with the locker above mine once showed me a Grateful Dead screen print he made in art class. I was blown away by how professional it looked. Ironically, I wasn’t allowed to take art classes—even though much of my career would be spent in the art and design world.

Around that time, I got deep into the punk rock and D.I.Y. scene. I’d already been using photocopiers for my guerrilla-style art projects—designing flyers with social justice themes and self-publishing zines. When I connected with other punk kids at school, I instantly became the go-to guy for band flyers and crack-and-peel stickers.

My First Taste of Screen Printing

When I got to college, I spotted a course offering offset and screen printing. I jumped at the chance—still thinking about that Grateful Dead print.

We were taught how to cut rubylith and use a line camera for separations. Toward the end of the course, I fell behind (thanks to falling in love), and was pressed for time on a 4-color separation assignment.

So I hacked it.

From my zine-making days, I came up with a workaround:

I traced each layer onto copier paper with pigment pens

Photocopied them onto acetate sheets

Doubled up and taped the acetates to get the opacity needed

Right as I finished the last layer, I got busted by the instructor—who happened to be giving a tour to a local print shop owner.

Not only did I pass… I got a job offer.

My First Press and a Hard Lesson from Germany

About a year later, a casual chat with a bartender led to me buying his 1-station, 4-color press setup—dryer, screens, squeegees, the works—for $2,000. I paid it off in a couple of weeks.

Thanks to connections I’d made with touring bands, I had a ready-made customer base. One band, prepping for their first European tour, wanted shirts printed in metallic silver instead of the usual white on black.

But I didn’t know that metallic inks reflect heat—and that infrared dryers need more time to cure them. I shipped out the order as-is.

A few days later, I got a call from Germany:

“The ink’s coming off after one wash.”

They were super cool about it, but it was a lesson I’ll never forget.

Learning by Trial, Error, and Grit

There was no YouTube back then. I didn’t know about trade shows or workshops. So for years, I learned by screwing up.

At times, I hated printing because I couldn’t predict what would go wrong next. But it was such a fast way to make money, I kept going.

And here we are.

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

The Coolest Jobs You’ll Never Hear About

Some of the most interesting, exciting, and even proudest moments I’ve had in this industry are wrapped tightly in NDAs. From the controversial to the downright cool, these projects span a wide spectrum—and while I wish I could share more, they remain under lock and key.

Full Circle: Printing for Childhood Icons

One of the biggest personal wins for me was getting to print for skateboard companies I grew up idolizing in my pre-teen years. Those logos and graphics that once covered my school books and bedroom walls? I got to put them on shirts and decks as part of my career.

And designing and printing for many of my favorite bands? Definitely a pinch-me kind of experience.

Where Passion Meets Purpose: Charity Prints

But when I think about the moments that truly stayed with me, it’s the charity prints.

These jobs came without creative constraints or commercial pressure, which meant I could use them to experiment and push my skills further. One that stands out most:

A group of school friends had drawn an image for a classmate fighting cancer. The artwork was made in coloured pencil, full of texture and warmth. I wanted to preserve every bit of that.

At the time, I was teaching myself CMYK process printing. It felt like the right technique to stay true to the art. When the job was done, the final print looked like a photograph of the original drawing.

That one meant a lot.

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

It seems like the thick street wear stye of printing is fading off quickly again and all over prints are back again. So I’m excited to help people learn how to print soft with higher detail again. I think because of content creators- we are seeing an increase in special effects printing.

On a recent trip to Mexico I was overwhelmed by how much brands in Mexico are embracing multiple special effects on mall level garment brands. We may see more of that here in the U.S. soon as a reaction to DTF printing which generally feels and looks cheap.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

Printing in the Pre-Internet Days

I really wish the online world existed when I first started printing.

While learning by trial and error taught me a lot, I now realize just how much time I lost. Time that could have been spent producing better quality prints, more consistently.

For the first 10–15 years of my print career, I didn’t even know other printers. There was no community. No shared knowledge. In fact, people actively protected what they knew.

Back then, we’d often go out of our way to spread bad info—just to safeguard hard-earned techniques. It was a different mindset. One rooted in scarcity.

A Shift in Mentality

When I took a job with Rutland Group as a Union Ink sales rep, I noticed something right away. The veteran I replaced only shared the bare minimum—just enough to get customers by.

It seemed like he did this to protect his own industry value. But when I started traveling solo, I couldn’t get behind that approach.

So I flipped it.

Ask anyone—I’m known for sharing everything I can, as quickly as I can. I don’t hold back. If we have 15 minutes to talk, I’ll pack it with as much value as possible.

Equipping Printers to Solve Their Own Problems

My goal is simple: when I leave your shop, I want you to have enough information to figure out your next issue on your own. And if something doesn’t stick? Just call or text me.

Now, with social media, I get to share that knowledge on a bigger scale. I can make videos that answer the same questions hundreds of customers might ask—and save us all time.

Of course, that comes at a price.

At trade shows, I’m usually hoarse by the end from talking with customers non-stop. But honestly? It’s worth it. Every conversation helps raise the bar for the industry.

Shop Floor

What is your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

What Every Printer Should Have in Their Toolkit

Every printer—whether they’re just starting out or 20 years in—should own two essential tools:

- An Atkins thermal probe

- A digital loupe

Why? Because understanding heat is critical to quality, efficient screen printing. A thermal probe helps you dial in proper curing, especially on poly and low-bleed inks.

Meanwhile, a digital loupe lets you inspect detail, assess over-cured inks, and check registration quickly—saving time and guesswork.

If you call yourself a printer, you should have a toolkit ready for the shop floor—equipped to troubleshoot on the fly.

Dryer Before Press. Always.

There’s a common misconception that the newest press with the latest features is the key to a better shop. It’s not.

Your dryer and your screen-making equipment are far more important.

Remember:

“You can only print as fast as your dryer can cure shirts.”

If you’re cranking up dryer speed to keep pace with your press, your dryer’s too small. And increasing belt speed usually leads to under-cured prints—a recipe for failure.

Quality Screens = Quality Prints

Let’s not forget the “screen” in screen printing. Your screens must be top-notch—not only for great print results, but also for efficient setup and durable ink film layers.

That’s why your exposure unit is arguably the most important piece of equipment in your shop.

I’ve seen far too many printers deep in debt over a brand-new press, while still using a fluorescent tube exposure unit that produces bad screens.

Get the best exposure unit you can afford. Then look at presses.

Prioritizing fundamentals like curing, screen quality, and exposure will always take your shop further than bells and whistles.

What is on your wish list for your shop floor this year?

No Shop, No Problem

I don’t own a shop anymore, but I regularly travel to Kennesaw, Georgia to work out of the Avient Specialty Inks print lab.

And if there’s one thing we can’t stop talking about, it’s getting our hands on a Laser to Screen (LTS) machine. Honestly, our bosses are probably sick of hearing about it.

Alpha vs. Beta: The Test That Said It All

Just a few weeks ago, we ran an Alpha test in the lab using our direct-to-screen (DTS) system and a new ink line.

The next day, we printed the exact same art for a Beta test at a local shop using a Laser to Screen machine.

The difference?

Tremendous.

Why LTS Matters—Especially for Sustainability

At Avient, we set annual goals to boost our sustainability efforts. One of the things I respect most about Laser to Screen technology is that there are no consumables:

- No wax

- No black ink

- No washout waste going down the drain

It’s a cleaner, more responsible solution—and the results speak for themselves.

I seriously can’t wait until we get approved to bring an LTS machine into the lab. It’s going to change everything.

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

Great—You’re Taking the Leap

So, you’ve decided to invest your life into screen printing.

Maybe it’s always interested you. Maybe you were the best press operator at your old job, and now it’s your turn to be the boss.

But here’s the reality check:

Being a great printer isn’t enough.

Understand What You’re Best At

Running a print shop means mastering more than just printing clean, on-time, and at a competitive price.

You need to:

- Know every step in the process

- Streamline and build repeatable systems

- Train others to follow those systems

- Own your tools and learn to maintain your machines

Decide early:

Are you building this to scale—or to sell?

And always know what your shop is worth. Be realistic about that number.

Don’t Ignore the Bookkeeping

If finances and analytics aren’t your thing, find a partner who thrives there. That could make or break your future.

I’ll be the first to admit it—bookkeeping is not my strength. If I build another shop, I’ll make sure someone else handles that side of things.

Own Your Building

Seriously—go into business with the goal of owning the property you operate in.

Why? Because life happens. Health insurance is expensive, and unpredictable events can throw everything off course. Owning your building gives you equity, flexibility, and potentially a lifeline if you need it.

Buy Smart, Not Flashy

Don’t buy gear at trade shows based on hype. Make equipment decisions based on ROI:

- How quickly will it pay itself off?

- When will it start generating profit?

- Does it actually solve an inefficiency in your workflow?

Hunt inefficiencies down like a predator. Every extra test print or misregistered job is money walking out the door.

I Can Build It All—But I Know My Limits

I sometimes joke that I could build a shop from the ground up:

- Clear the lot

- Erect the building

- Assemble machines

- Map out workflows

And I’ve done it.

But what I’ve learned is this:

You need to know what you’re not good at.

And be smart enough to bring someone in who is.

Bonus

- Share a funny or unexpected mishap you’ve encountered while screen printing.

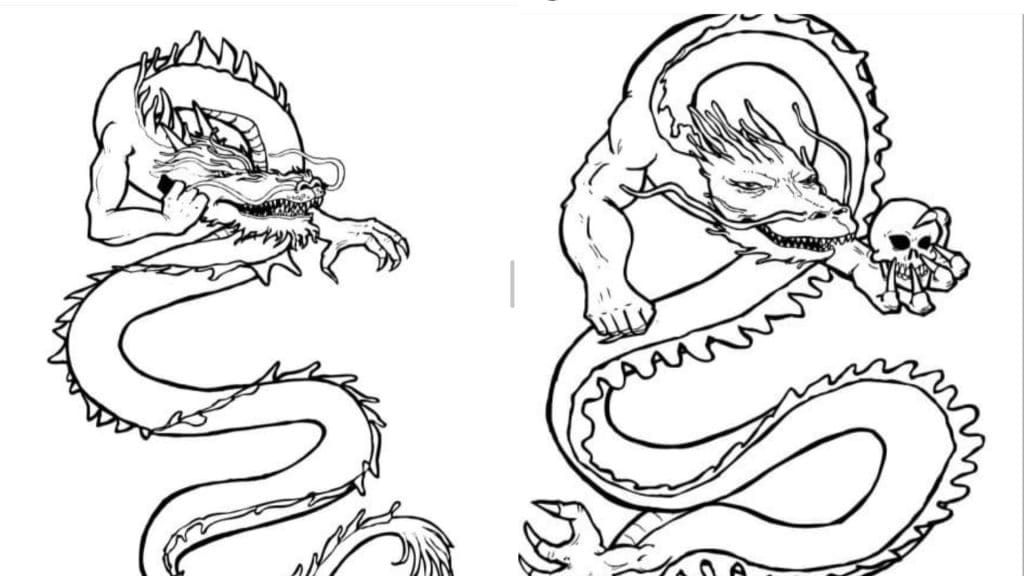

I had a customer that owned a supplement company and requested a new design with a dragon holding a skull in its claws. In my shop we hand drew most of the mock-ups and then finished them out in Illustrator or Photoshop.

So, I ask one of my artists to draw up a Dragon holding a skull and once that was approved I planned to add the text and punch up the art. Well, he comes to me with a sketch of a Dragon holding a cell phone to his head like it’s taking a call… I call the artist back into my office and I’m like “what the hell is this? The dragon is supposed to be holding a skull!” And the artist simply says “Ohhhh, that makes so much more sense, I thought you said a dragon holding a cell” and returns with a new sketch.

- What’s your go-to playlist for a productive printing session?

Oh man, this is kind of embarrassing. I love punk and metal and fast music so I want to give you some epic playlist filled with obscure band names- but, when it really comes down to just pumping out hundreds or thousands of shirts we would put on “Girl talk” which is a mash-up artist who has a couple of tracks that are around an hour long each at a fast BPM.

Otherwise, if I’m just cruising on press alone- I’ll listen to Sleep or some other desert rock band. My current “get shit done” play list consists of Queens of the stone age, Kyuss, Sleep, Red Fang, Rye Coalition, Hot Snakes, The Sword, The Stooges, Janes Addiction, Mastodon, Baroness, Wolfmother, Speed wolf, The Hives, Black Sabbath, Blue Oyster Cult, Motorhead, Alice in Chains, High on Fire, Brujeria, Iron Chic, Off With their heads, The Clash, At the Drive in, and The Donnas. Take away the gimmick and the Donnas have some great guitar driven songs.

- What is the weirdest/funniest artwork you’ve had to print?

Well, it would just be in poor taste if I shared the weirdest artwork I’ve printed.

I did have an amazing CMYK on discharge base print I did for an organic egg farm where the art was of the two owners who are shirtless with farmer tans in the image. There were 3 things asked of me that the previous printers were not able to achieve.

- The eggs needed to be brown and not green.

- Their tans needed to be realistic. Bronze and not pink.

- They wanted the detail of their arm and chest hair to be visible and not blurry.

I was able to do all of this with CMYK + discharge base, top white and a Pantone vector screen for the text and the customer was over the moon about it. I stayed up all night burning screens, test printing, then making corrections in Photoshop, and burning the next set of screens. I watched my staff go home for the night and then come back the next morning while I was still on press.

Another funny job was for a marriage councilor. Remember the movie “Office Space” and the game “Jumping to conclusions” that one of the characters invented. Well, this councilor wanted to print these great big mats that a couple stood on. Each player would move from one triangle to the next based on questions they answered and eventually end up on the same triangle. I had to print each section on a large Filbar flat bed press and then whole thing was sewn together to create the “game board”.

Conclusion

From punk flyers to CMYK masterpieces, solo road trips to cutting-edge labs, John MaGee’s screen printing journey is a blueprint in resilience, reinvention, and raw curiosity. Whether he’s troubleshooting on the shop floor, sharing knowledge at trade shows, or chasing better print quality with every test screen, John’s legacy is one of generosity and grit.

In an industry that’s constantly evolving, John reminds us of something vital: the tools change, but the passion, precision, and community spirit are what truly keep this craft alive.

Thanks for going Behind the Mesh with us. Stay tuned for more real stories from the people who shape print—one screen at a time.