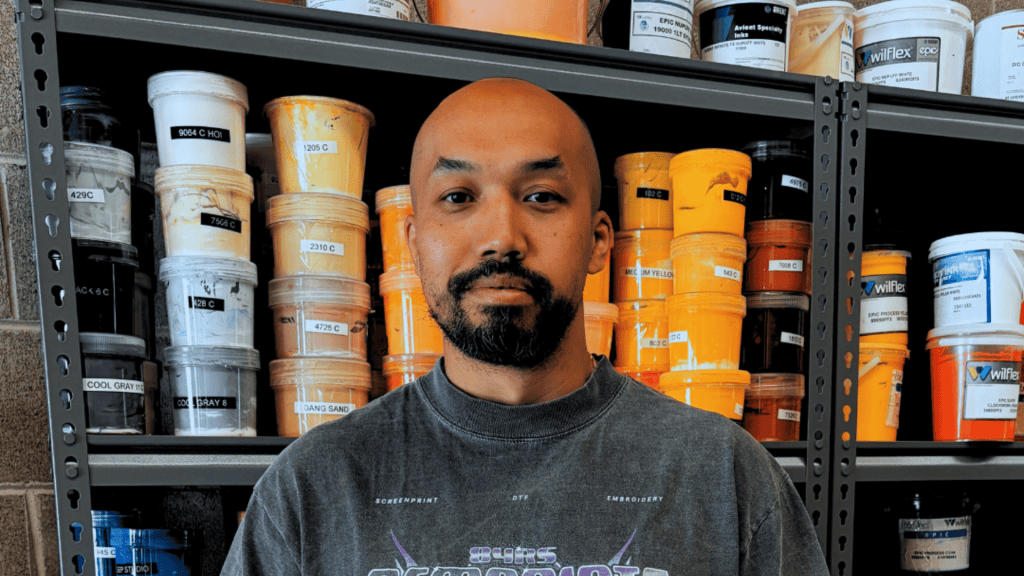

Getting to know Ply owner of Nemprints

Behind every print shop is a story that doesn’t show up on Instagram feeds or order forms.

Behind the Mesh is about the people who built their businesses from curiosity, late nights, mistakes, wins, and a lot of figuring it out as they went.

In this edition, we sit down with Ply, owner of Nemprints Screenprinting & Embroidery, to talk about how a fascination with screen printing turned into a full-time business — and what he’s learned along the way.

From printing merch for dance crews on a kitchen table to running a professional shop, Ply shares the moments that shaped his journey, the gear he swears by, and the advice he’d give anyone thinking about jumping into the industry.

Let’s dive in.

Keep up with Ply and Nemprints on:

Instagram: @nemprints.au

Website: www.nemprints.com.au

About Ply

List 3 things about yourself – fun facts, hobbies, pets or interests

- Grew up in New Zealand and moved to Melbourne in my early 20s

- Was an amateur boxer and was a Boxing personal trainer for a brief period

- Screen printing is my first business venture

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

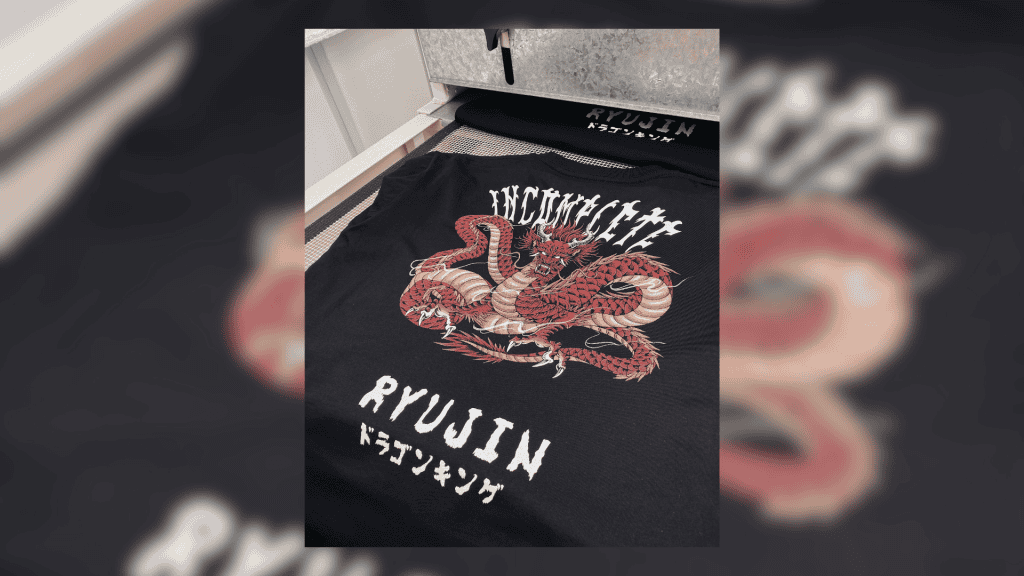

First saw screen printing back in 2015 when doing uniform and merch for my dance crew and was super fascinated about it as I always wanted to own a clothing label. Started making our own uniform for the crew with a vinyl heat transfer and then bought a chinese eBay press to dabble in screen printing and learned off youtube videos. In 2017 I was printing uniform and merch for most of the dance crews in Melbourne and realised this could be a business and launched Nemprints from there.

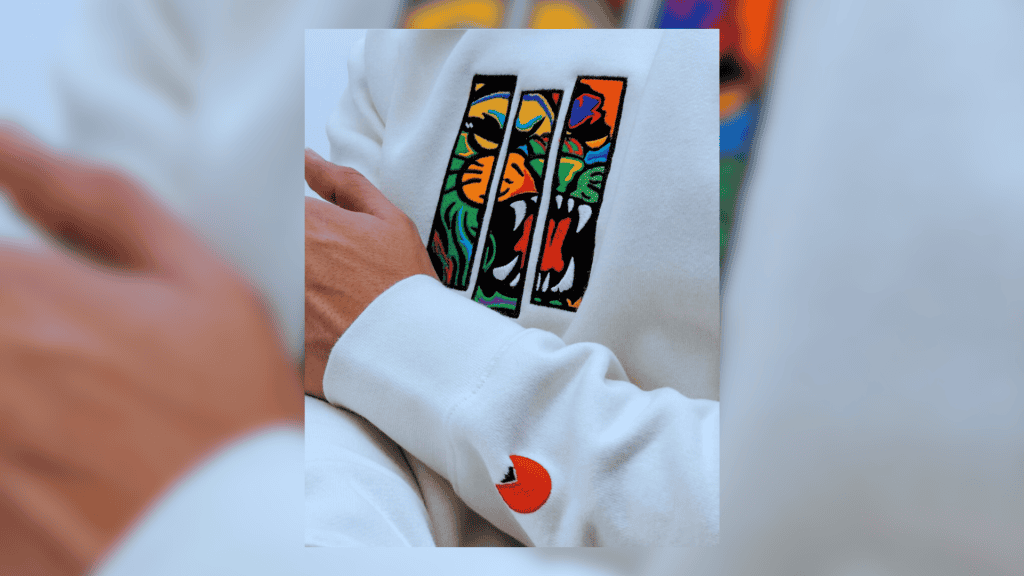

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

Nailing my first halftone gradient print. It’s not my most technical print or anything but at the time I didn’t have any fancy software, just photoshop and an endless supply of tutorials on Youtube. It was my first time doing colour separation and printing half tones and also wet on wet, I had to remake the screens 3 times to get it right but once I nailed it, it felt like I could proudly call myself a screen printer.

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

I see Direct to Film trending into the industry, and I’m all for it. It’s just another tool to get the job done. Not everyone is looking for retail quality prints, some people just need something funny to wear at a Bucks or Hens party. And if it’s a few less screens to reclaim, that’s always a bonus to me.

One emerging technology I’m excited about is Direct to Embroidery! Where you can digital print over white thread of an embroidery image. It looks like it’ll dramatically decrease production time and costs for embroidery.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

The online community plays a big role for me. The screen printing community in Australia are super friendly and helpful. Most are willing to connect and share knowledge if you simply just ask politely.

I also learn a lot from the Facebook groups, there’s a lot of knowledge floating online if you’re willing to search and take it in.

Shop Floor

What is your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

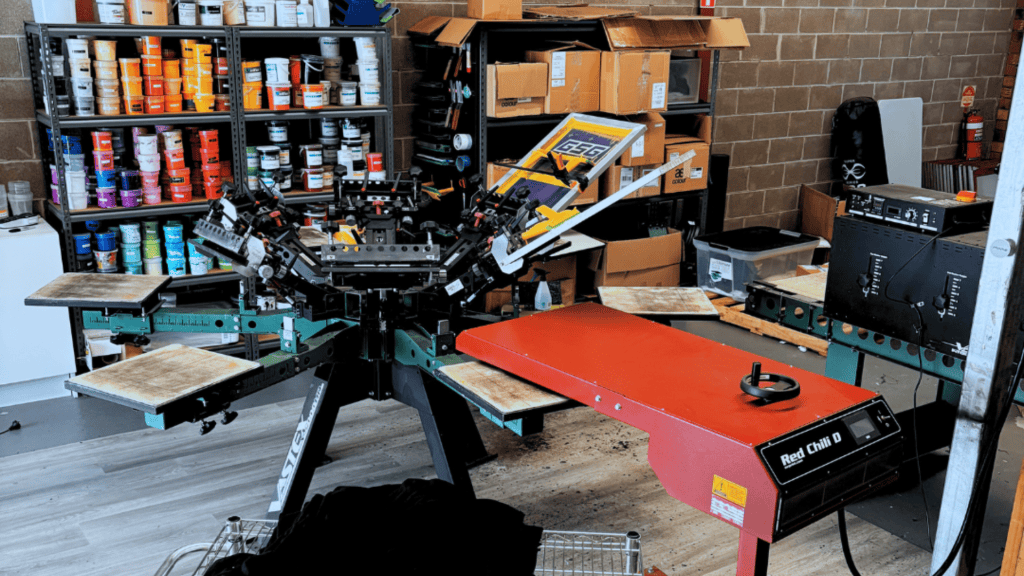

There’s 2 pieces of equipment that I treasure, the 1st is my Vastex press. Going from a cheap eBay Chinese press to this made a world of difference with quality and efficiency. It also holds registration incredibly well and decreased my spoilage rate.

The 2nd piece is more of a luxury item but it’s the Red Chilli Flash Dryer. Before this we went through 3 cheap flash dryers that kept overheating and breaking on us. The best thing about the Red Chilli is the sensor that measure the temperature of the t-shirt and turns off when it hits the temp you set it at. So not absolutely essential but really love it for that feature alone as it eliminates over flashing or underflashing.

What is on your wish list for your shop floor this year?

Same thing I wish for every year, an automatic screen printing press.

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

Being good at screen printing is essential but it’s not enough if you want to run a business. Your printing skills will get better with time and reps but I feel like it’s even more important to know how to do marketing and sales. So don’t wait till you’re good at printing to learn how to market and make sales, work on it all at the same time, you need them all.

Bonus

Share a funny or unexpected mishap you’ve encountered while screen printing.

I always look back and laugh at my first screen printing order for my crew, I didn’t have a press yet, so I printed everything on the kitchen table with my gf holding down the screen for me, no off-contact, I got ink on the curtains. Then because I’m self taught, I didn’t know you still had to cure waterbased ink so I just laid it all over the couch to dry and then delivered them to everyone. Of course it all washed off after the first wash and I had to refund everyone for it.

What’s your go-to playlist for a productive printing session?

For a chill day and long runs, I’ll chuck on some Trance, particularly some Above and Beyond.

When I’m working by myself and need to get cranking, it’s usually 2000’s Hard Rock playlist

What is the weirdest/funniest artwork you’ve had to print?

Everything is usually pretty tame but I always get a laugh when people do Bucks and Hens party tees and send through unflattering images of the Bride or Groom.

Conclusion

Building a print business doesn’t happen overnight — and it definitely doesn’t happen without mistakes.

Ply’s journey with Nemprints is a reminder that curiosity, persistence, and a willingness to learn can take you a long way, even when you’re starting with limited gear and zero formal training.

Whether it’s mastering halftones, upgrading equipment at the right time, or learning that marketing matters just as much as print quality, his story reflects what so many printers experience behind the scenes. Because behind every finished print is a process — and behind every shop is a person figuring it out as they go.