This May, Behind the Mesh puts the spotlight on Matt McInerney, co-owner of Jones Brothers Printechnology. Matt’s story is rooted in family and forged through hands-on experience, starting at just 15 with school holiday shifts at his dad’s ink business, Australian Specialty Inks. From there, he developed a technical fluency in everything from solvent blends to diagnosing press issues – skills that laid the foundation for a career in screen print supply and support.

After joining Jones Brothers in 2006 and taking ownership with his wife Nichole in 2019, Matt has remained a vital voice in the Australian screen printing scene. Beyond the ink room, he’s a self-confessed sport nut, pet lover, and weekend golfer – when time allows. His sharp eye for industry shifts, such as the rise of low-cure plastisol and the resurgence of matte high density and flock finishes, shows a deep respect for both tradition and innovation in the trade.

Follow Matt and Jones Brothers on:

Website: www.jonespt.com.au

Instagram: @jonesptaus

About Matt

List 3 things about yourself – fun facts, hobbies, pets or interests

- I love playing golf (when I get time anyway!)

- We have a bunch of animals, two dogs, an old cat that was a stray, and three fish.

- I am a sport nut if there is a ball involved I love watching or poorly participaiting lol. This could be cricket, golf, league, or AFL.

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

I entered the screen printing industry by working for my Dad at Australian Specialty Inks (now Prismatic Inks) in Sydney. I started at the tender age of 15 doing school holiday work, then started full time at 18. It was there I was taught the in’s and outs of graphic ink manufacturing, and all things technical relating to that, including deciphering printing issues and identifying solvent blends.

I met Nichole through work as Jones Brothers was a distributor and moved down to Victoria. I started at Jones Brothers in 2006 and the rest is history! Nichole and I took over Jones Brothers in November 2019.

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

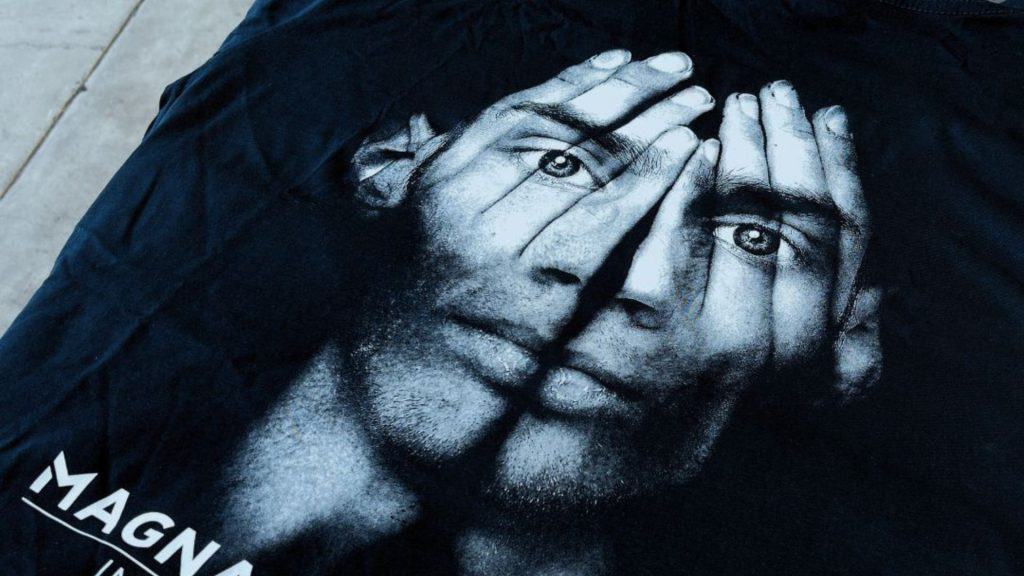

One of the proudest screen projects was creating the Magna Colours promo screens for the “Make Screen Printing Great Again” Trade Night at T-1 Print in Sydney. It was an 8 colour job for Magna Colours water based inks, using a 77T base and 120T colours. What it taught me is that I am definitely not a screen printer (I tore a screen on press!), I need to stick to being an ink nerd! However, the images and garments turned out amazingly!

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

Low cure plastisol ink is becoming highly popular, not only does is save on energy, it assists with the printing of all those nasty fabrics that hate heat. I think that standard cure plastisol will become a thing of the past in the next 5 years.

I like that everything old becomes new again with print trends. Matt finish high density has been popping up, and I have noticed that flock finishes have appeared also. I guess that you wouldn’t call them emerging techniques as such, however to screen printers that are newer to the market it will be a fresh technique for them and allows printers to use their creativity to put a fresh spin on how they use them in their designs.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

I’m pretty old school in that respect – most of the time I am talking with printers on the phone or in person to nut out issues or provide solutions. However, we produce monthly blogs focussing on a particular topic which are shared to our online audience – I like that we can share our knowledge with our customers over many platforms.

I regularly use online forums, the web, and Instagram for product research, and for searching for emerging trends.

Shop Floor

What is your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

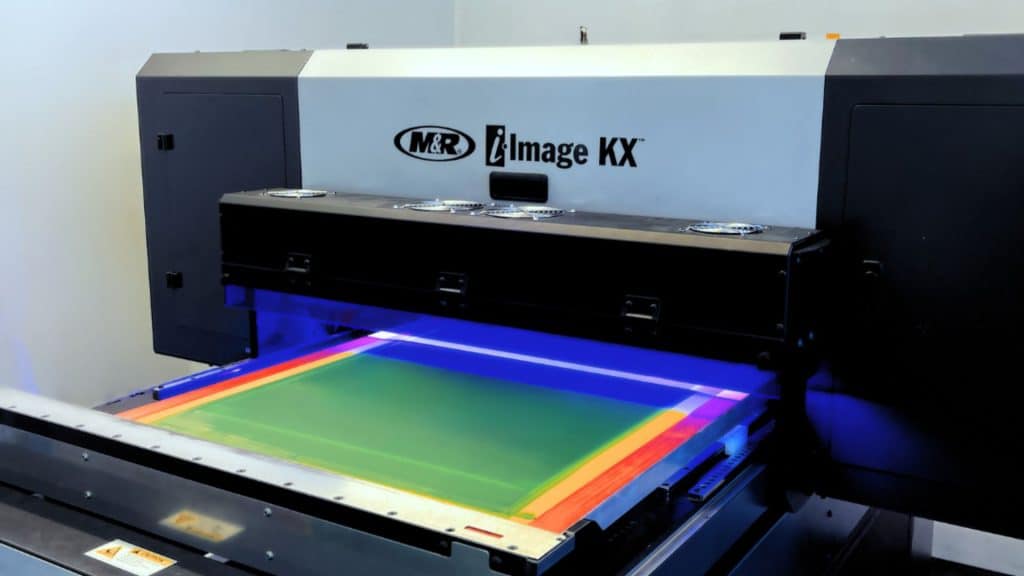

While I obviously am not a screen printer, there are a couple of things that we have added to the business which has improved workflow and efficiency. One being the automatic meshing table – a touch of a button, and the screens are being meshed to individual customer specifications without intervention. The second being the M&R I-Image – this is a game changer for exposing screens. Where it is of most benefit is for high detail images and accuracy.

My most treasured personal product though that I have carried with me over the years is my set of three ink knives!

What is on your wish list for your shop floor this year?

An auto coater for the exposure room.

And Computer to screen that would then supersede the I-Image eventually.

Who knows maybe a DTF machine to play around with

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

Do you your research – Youtube is good, but not the bible. Make sure you research & practice and perfect your stencil making. Its called “screen” printing this the foundation to any quality screen job.

Bonus

- Share a funny or unexpected mishap you’ve encountered while screen printing.

So many….. I was using our high-speed mixer to blend a batch of metallic blue Pantone UV ink. Instead of easing the speed down like a sensible operator, I accidentally cranked it up.

Next thing I know, the mixer throws a full-body tantrum—and I cop it from chest to toe. Metallic. Blue.

I had to evacuate the ink room and the warehouse, strip off in true hazard-response fashion, and make a beeline for the shower. I looked like a rejected X-Men character—Pantone Man.

Lesson learned: check the dial, respect the RPM, and always keep a clean change of clothes on standby.

- What’s your go-to playlist for a productive printing session?

My spotify is a blend of a mix. I have 90s rock, 2000`s rock, and mix of country music.

- What is the weirdest/funniest artwork you’ve had to print?

We see so many, the most confronting one was an art exhibition of dissected men’s appendages.

Conclusion

Matt’s journey shows that true expertise in screen printing goes far beyond just pulling a squeegee. It’s about understanding the chemistry, anticipating industry shifts, and being ready to laugh off a metallic blue explosion now and then. His favourite tools? A well-worn set of ink knives and an eye for detail sharpened by years of trial, error, and success on the shop floor.

From phone calls with customers to late-night stencil prep, Matt’s story reminds us that passion and patience are key to lasting success in the print world. His advice to newcomers is simple but powerful: research deeply, perfect your stencil, and respect the process. Because in screen printing, it’s not just about laying down ink—it’s about laying the groundwork for something great.