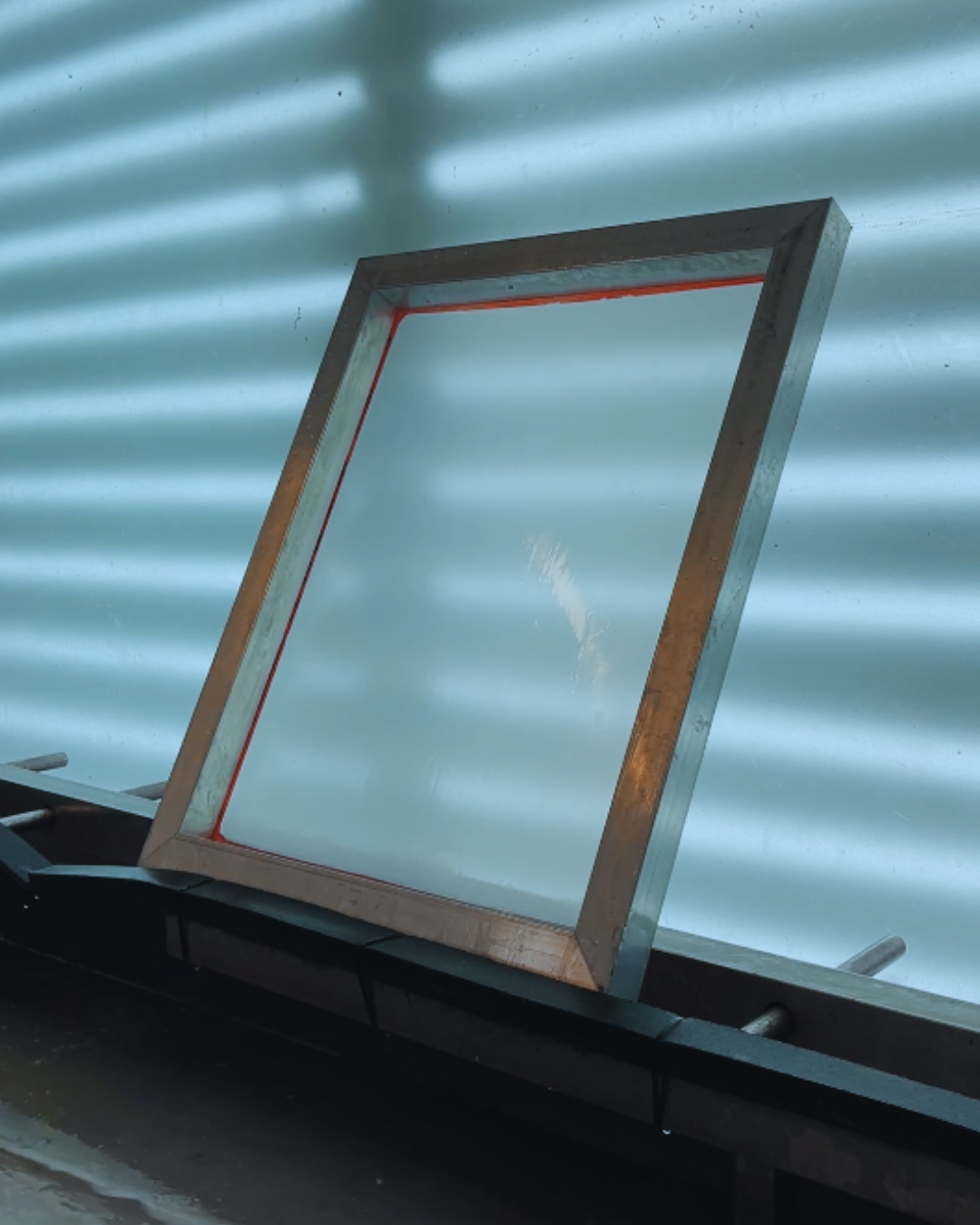

Degreasing your screens before applying emulsion is one of the simplest yet most essential steps in screen printing. Whether you’re a beginner or have some experience, understanding this process can significantly improve your print quality. Here’s why:

1. Clean Screens = Better Prints

A clean screen is crucial for getting the most out of your emulsion. Oils from your hands or dust from the environment can block the emulsion from adhering properly, leading to uneven coating and poor-quality prints. By degreasing, you ensure that the emulsion spreads smoothly across the screen, creating a more consistent and even surface. This results in sharper and more detailed prints, no matter the design.

2. Improve Emulsion Adhesion

One of the main reasons to degrease your screen is to improve the emulsion’s ability to bond to the mesh. Without this, the emulsion can peel or flake off during printing, leading to wasted time and materials. Degreasing ensures a solid bond between the screen and emulsion, which in turn increases the durability of your screen throughout the printing process. This step can save you from headaches like peeling stencils or the need to recoat the screen.

3. Reduce Pinholes

If you’ve ever had small, unwanted holes (pinholes) appear in your stencils, you know how frustrating it can be. These often occur when oil or dirt creates tiny air pockets under the emulsion. By thoroughly degreasing your screen, you significantly reduce the risk of pinholes, leading to smoother prints with fewer imperfections. This saves you time on corrections and touch-ups, making your workflow more efficient.

4. Enhance Stencil Quality

For high-detail jobs, degreasing becomes even more important. A clean screen allows the emulsion to form a crisp, sharp stencil, essential for producing detailed designs or small text. Without proper cleaning, your stencil can turn out blurry or inconsistent, which is especially problematic for fine artwork.

5. Prevent Contaminants in Printing

Any contaminants left on your screen—whether it’s dust, oil, or other residues—can affect how the ink transfers through the mesh. This could compromise the quality of your final product. Degreasing your screen ensures a contaminant-free surface, so your ink transfers cleanly and accurately onto your substrate, avoiding unexpected smudges or flaws.

6. Professional Results, Every Time

Taking the time to degrease before every emulsion application is a small step with big benefits. Not only does it speed up production by preventing issues, but it also boosts the quality of your prints. Clean screens help you maintain professional-grade results every time you print.

Conclusion

Degreasing may seem like an extra task, but it plays a crucial role in maintaining the longevity of your screens and the quality of your prints. Whether you’re just starting out or have some experience, making degreasing a habit will pay off in the long run, ensuring cleaner, crisper prints with fewer issues along the way.

Start incorporating this step into your screen preparation process today, and watch your prints improve!

Product Recommendations

- Franmar D-Grease – Degreaser

- FOTEC 2023 – Gel Degreaser & Abrader

- Chromaline Clean Degreaser

- SAATI Direct Prep 2 – Degreaser

View our degreasing range here