Getting to know Ben Carroll owner of Velflex

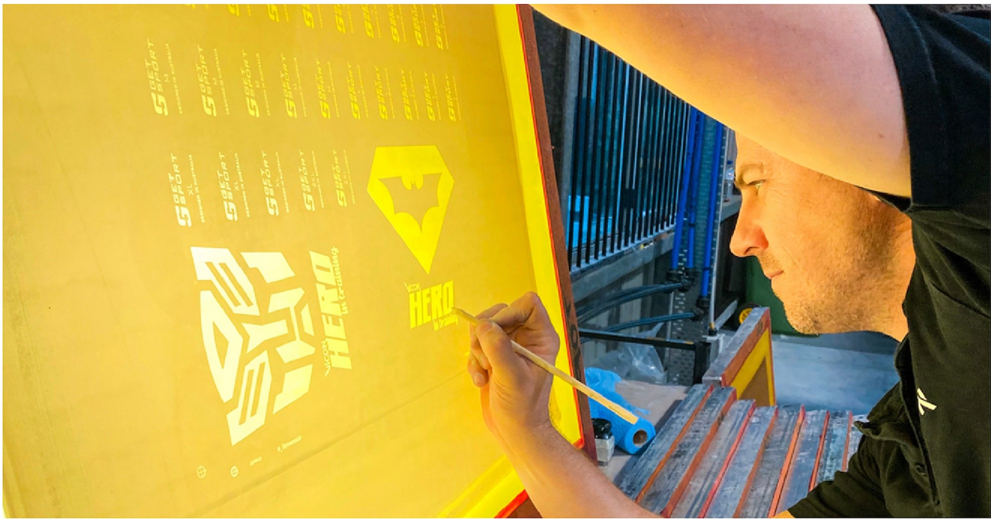

Meet Ben Carroll, an entrepreneur with an illustrious 18-year journey shaping the landscape of heat transfer products, starting from humble beginnings with a sheet-fed screen printing machine. As the proud owner of Velflex, Ben has not only mastered the art of creating vibrant, durable and high-quality transfers but has also become a trailblazer in supplying top-notch heat presses, printers, and essential materials to the industry.

Ben is not just a business owner; he is a maestro who has dedicated nearly two decades to perfecting the craft of heat transfers. Ben’s expertise is not only a testament to his passion for the art but also an embodiment of the commitment to delivering unparalleled quality to clients.

What sets Ben apart from the crowd is his groundbreaking hybrid digital screen printed transfer creation – Ultracolour Transfers. These revolutionary transfers have become the hallmark of excellence in the industry, gaining widespread acclaim and adoption, particularly among garment decorators around Australia. The Ultracolour Transfers have redefined the game, elevating the visual impact of designs and setting a new standard for quality in the world of heat transfers.

Behind the Mesh delves into the behind the scenes of the business of Velflex and gets to know the owner, Ben Carroll. Find out what Ben likes to do in his spare time and his advice to anyone looking to step into or wants to grow within the screen printing/printing industry.

Thanks for your time and participation in this series, Ben!

For more information about Velflex, head over to velflex.com.au and check out Velflex’s amazing product range, now partnering with us to bring you screen printing goodies!

About Ben

List 3 things about yourself – fun facts, hobbies, pets or interests

1. Music is my hobby outside of work, mostly playing guitar these days but younger years was club DJing.

2. I wanted to be an aerospace engineer before getting into the print business

3. The sport I most enjoy watching and following is Formula One.

Describe your screen printing journey. How and when did you get started and what has been your biggest learning experience?

I bought a sheet fed screen print machine, and a couple months later my operator resigned so I had a 3hr crash course before he walked out the door on how to run it and essentially how to screen print. The rest I worked out along the way asking plenty of questions and making lots of mistakes.

Tell us about your proudest screen printing project. What made it special and what did you learn from it?

In 2016 I worked out how to do a hybrid digital screen printed transfer called UltraColour, using the right water-based ink and catalyst combination. To get perfect registration behind the digital image I needed to have the perfect screen tension, right squeegee and absolutely the least amount of off contact. Took many attempts but once worked out, magic!

Industry

What are your thoughts on the current trends in screen printing? Do you see any emerging styles or techniques that excite you?

Puff effect has really taken off, especially in the gym and fitness space but also fashion garments.

What role does the online community play in your screen printing practice? How do you connect with other printers and share knowledge?

When we were developing our processes and getting different issues arising we often posted about it online, getting feedback from others. It might have been castling or moire effect we were struggling with and often it was the online community that would give ideas to think about.

Shop Floor

What your most treasured product or piece of equipment on the floor that has made your life easier as a printer? Why?

Our automated screen reclaiming system has made a significant impact on reducing chemical usage and contact, significantly faster and easier too, just keeps going reclaiming over 700 screens per day!

What is on your wish list for your shop floor this year?

A squeegee cleaner would be awesome! Or an ink mixing system for doing colours easily and accurately.

Advice

What advice would you give to aspiring screen printers? What are the essential skills and qualities for success in this field?

Attention to detail, particularly in making the screen stencil. Anyone can print an average quality screen print, but the perfect snap, screen tension, squeegee angle/hardness, mesh count all play an important role in getting the perfect print quality and printing something you’re proud of.

Bonus

What’s your go-to playlist for a productive printing session?

Progressive Trance/House is my go-to for a long evening print run, high tempo, good builds and breaks with solid vocals. Keep you printing for hours!

Ben is building amazing momentum in the screen printing industry, from small and humble beginnings Ben has grown Velflex into a staple in the garment decoration industry in Australia. We’re honored to be partnered with Velflex, offering us the opportunity to work closely with Ben and his awesome team.

We’ll be keeping up with Velflex and their plans for the future, who knows, there may even be a part 2…

Written by the Jones Brothers Printechnology Team in collaboration with Ben Carroll, owner of Velflex.